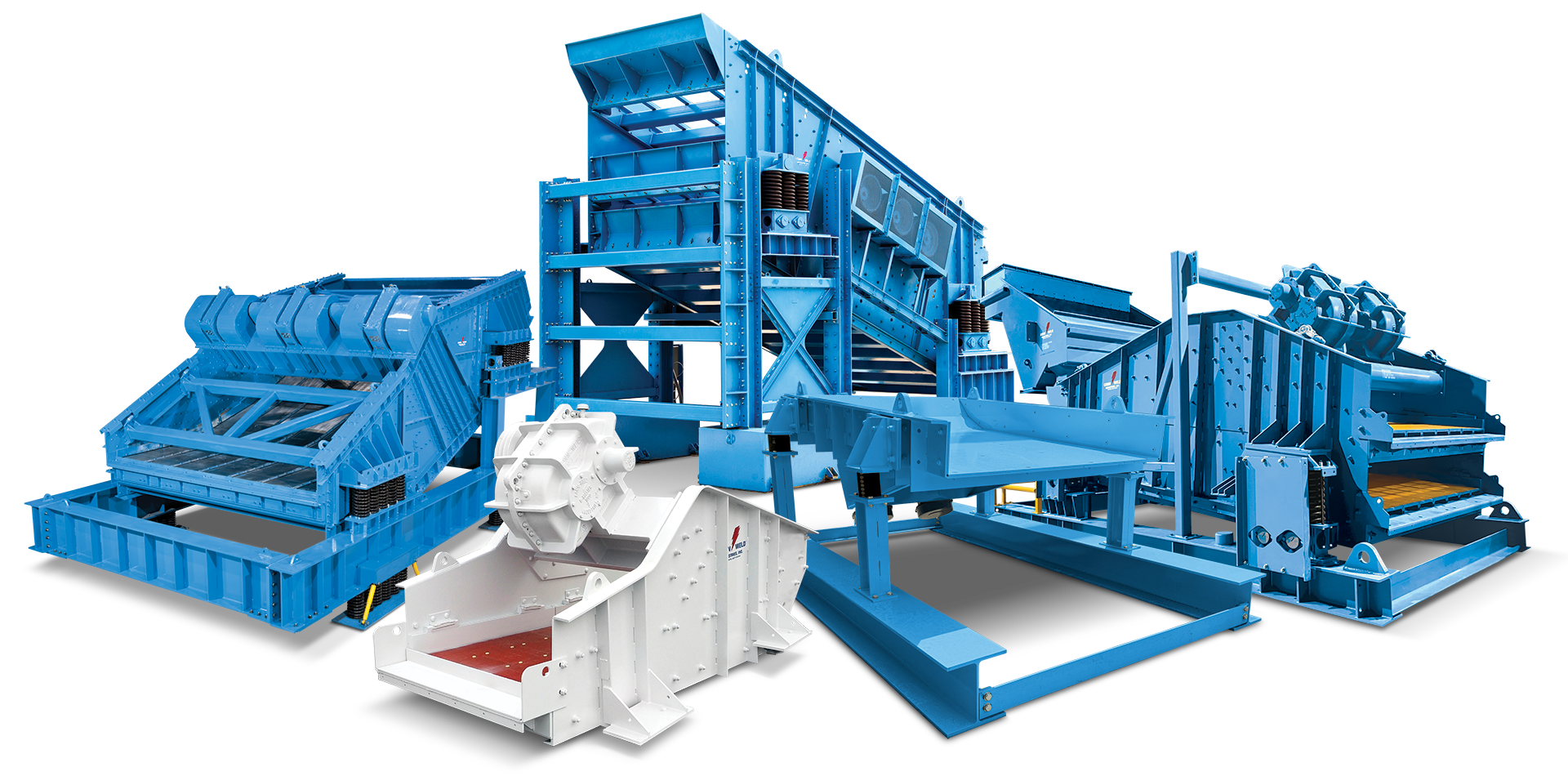

Conn-Weld custom manufactures a full line of vibrating screens (shaker screens) and parts for your screening applications.

Browse Products

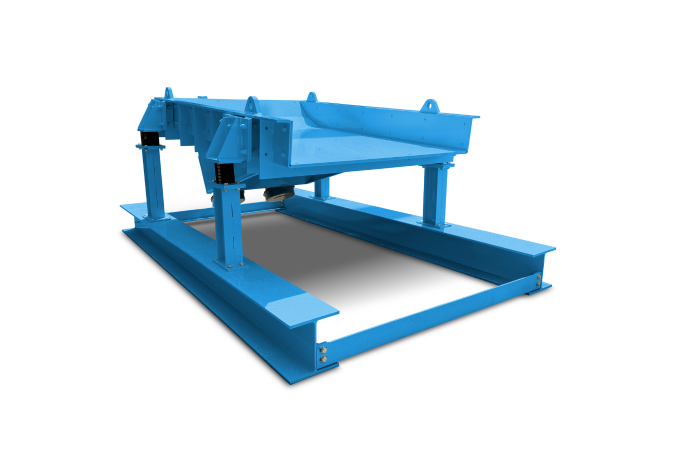

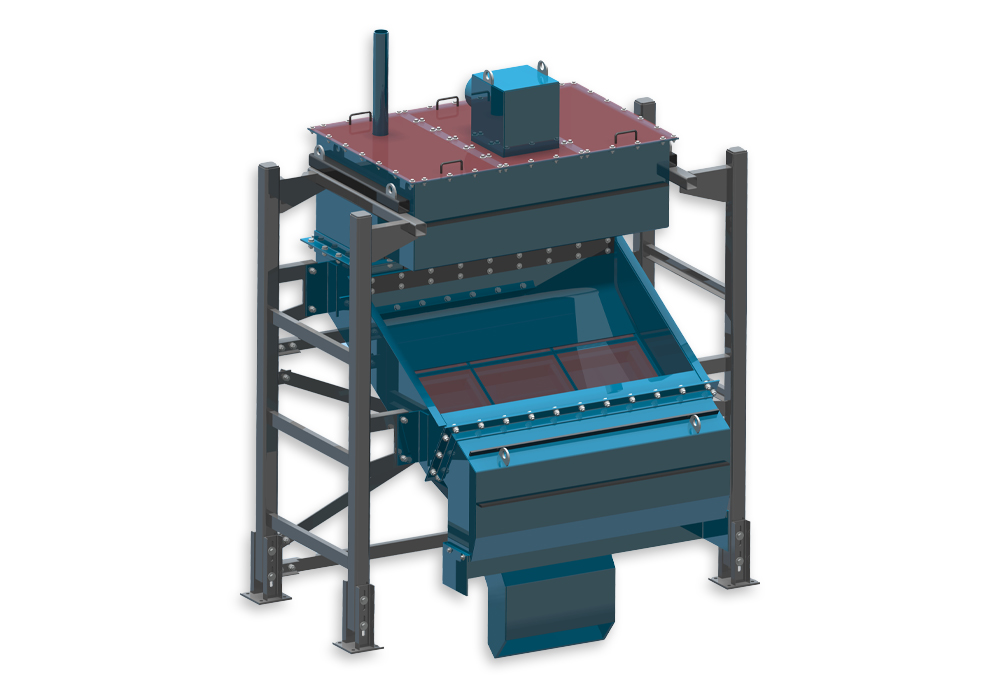

Conn-Weld vibratory pan feeders are designed for reliable, consistent material flow in demanding environments.

The Conn-Weld Elliptical Horizontal speaks to years of dedication for innovative solutions in unique challenges.

Conn-Weld’s High-Frequency Dewatering Screens are designed to handle the toughest challenges in screening – dewatering.

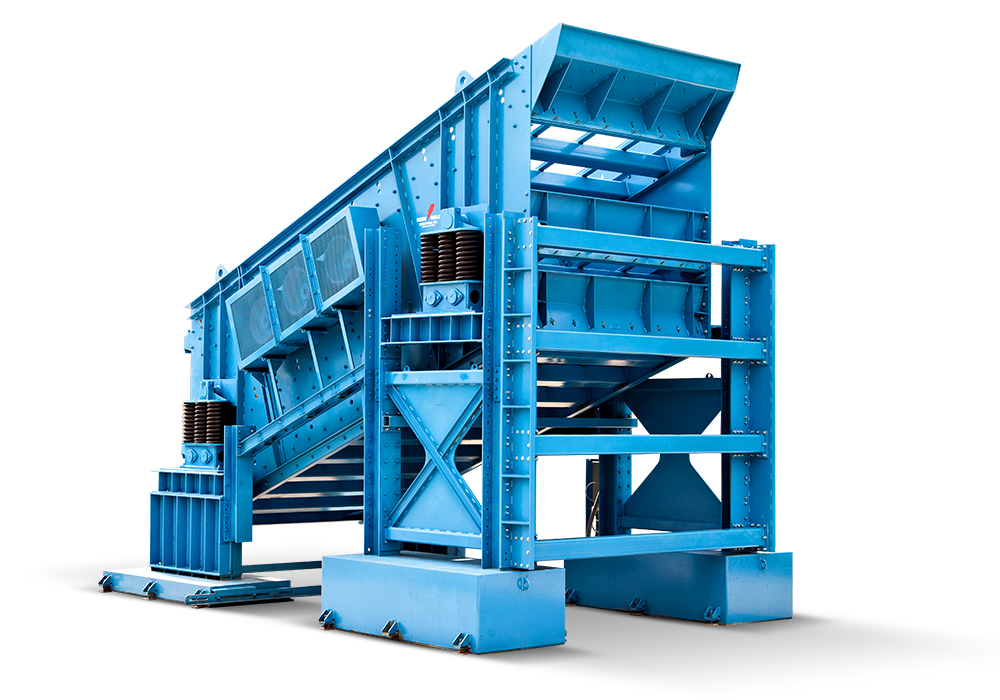

Conn-Weld’s Extreme Duty Scalping Screens stand up to the most demanding applications and large tonnages.

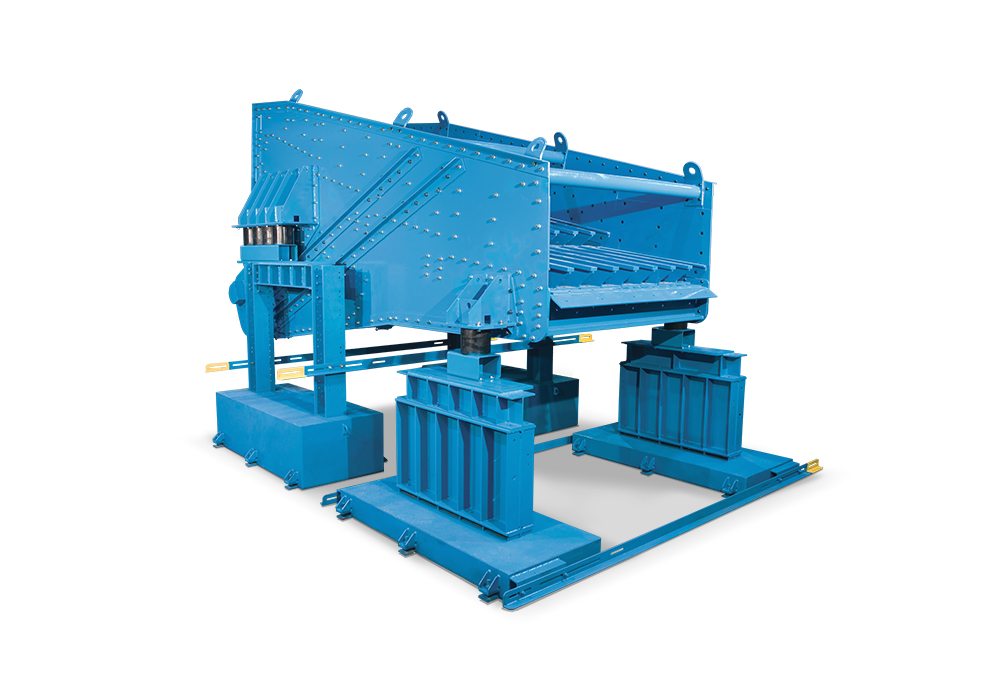

Conn-Weld Incline Screens are designed for numerous applications, from primary scalping to finishing wash screens.

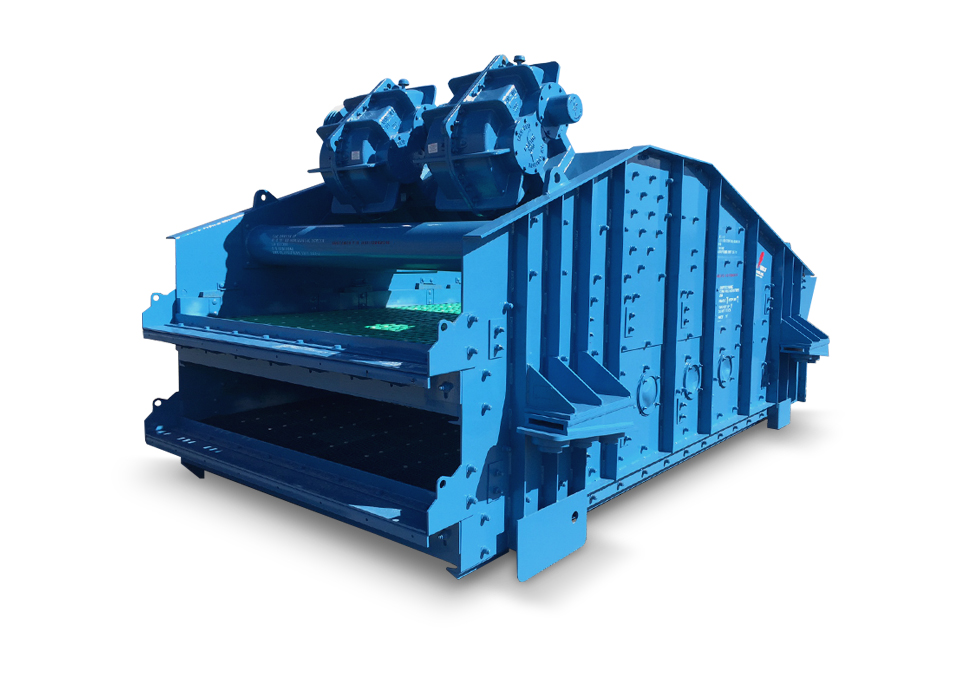

Conn-Weld’s Horizontal Screens have proven performance in every application.

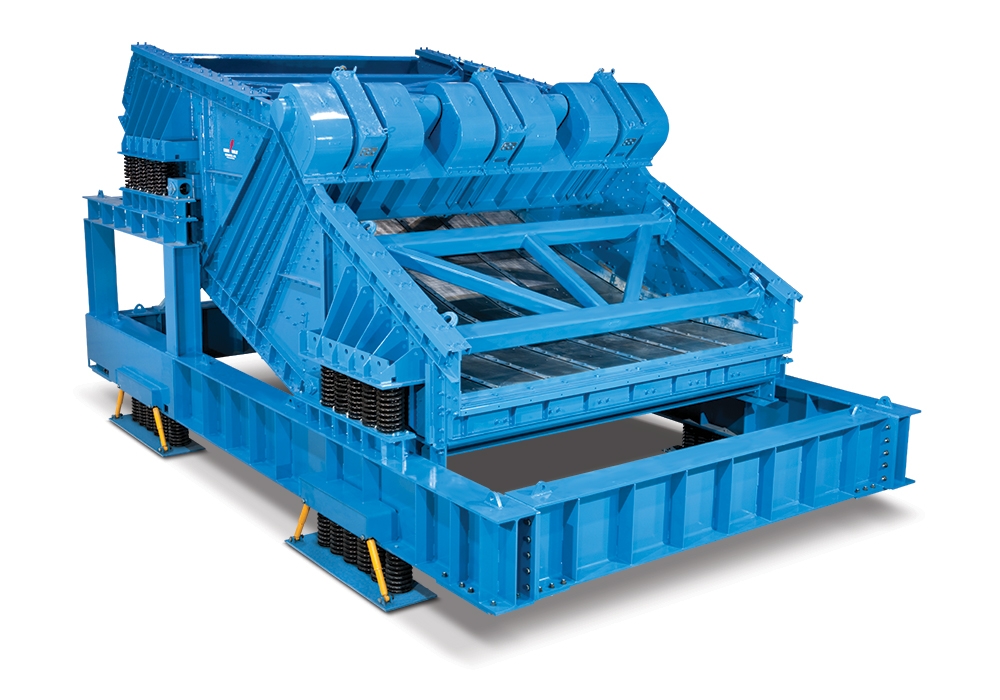

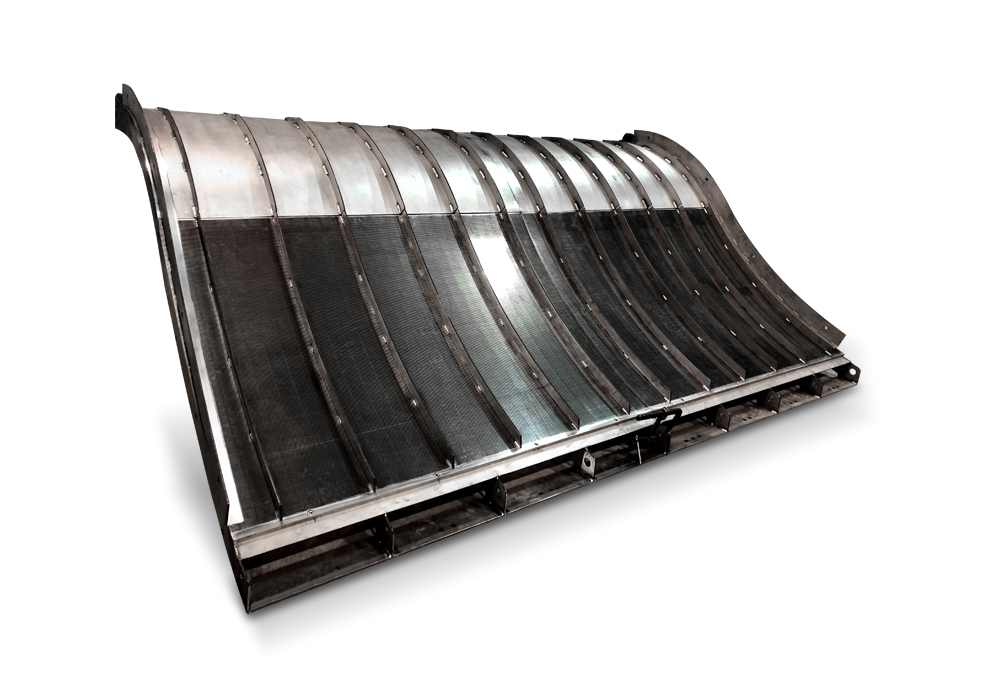

Conn-Weld’s Banana Style Screens offer superior quality and high-capacity screening. To ensure proper fit, we pay close attention to every unique request.

Conn-Weld Profile Sieve Screens are manufactured with a sharp cutting edge to efficiently slice away the slurry.

Typically upstream of a Vibrating Screen for most efficient slurry cut and recovery while feeding the Vibrating Screen in a laminar fashion.

A “green solution” for water treatment applications, Hydro-Sieve is an efficient sieve using proven technology to screen out sediment and aquatic life.

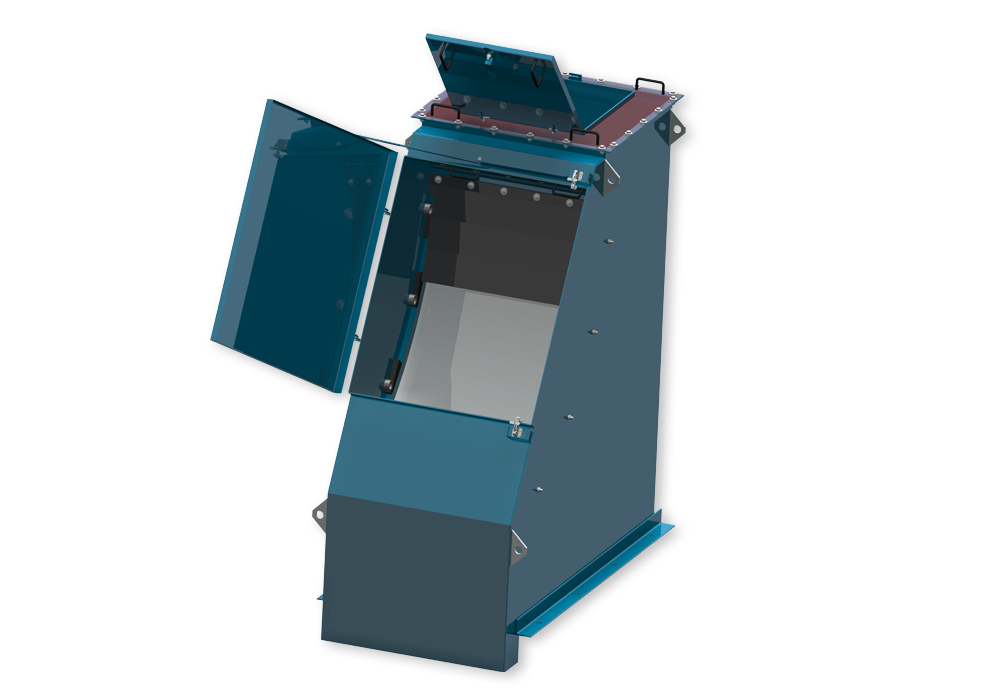

A fully customizable, self-contained unit. Can be pressurized or open/vented to atmosphere.

The performance of our full line of centrifuge screens begins with the wire. Through extensive research at our wire plant, we have developed a “high-edge” wire, capable of generating close tolerances and sharp leading edges to break surface tension.

Conn-Weld’s exclusive wedge wire baskets are the most durable in the industry, utilizing a patented fusion-welding process.

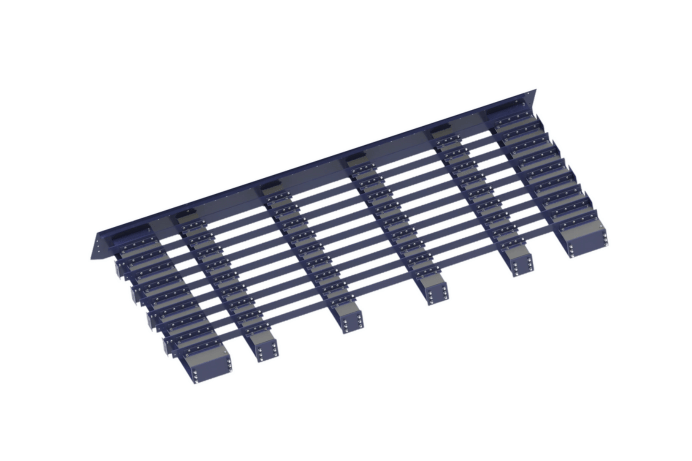

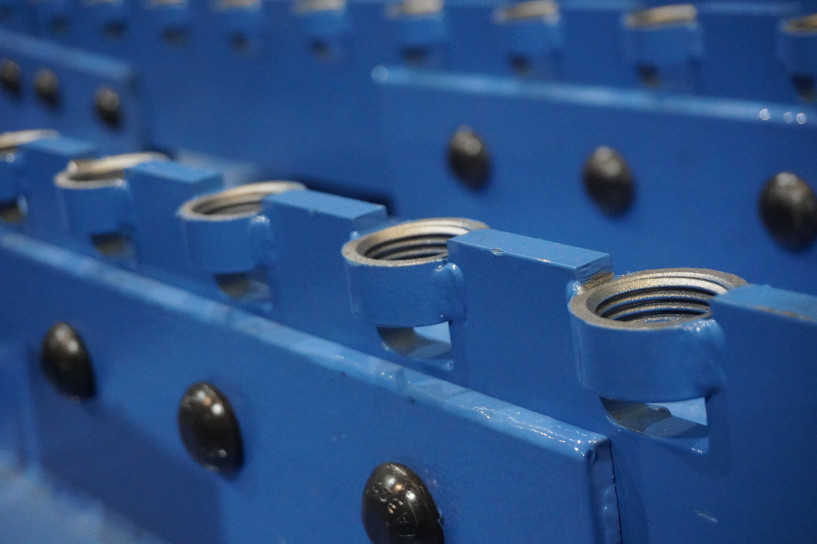

Individual Crossmembers allow for replacing parts as they wear.

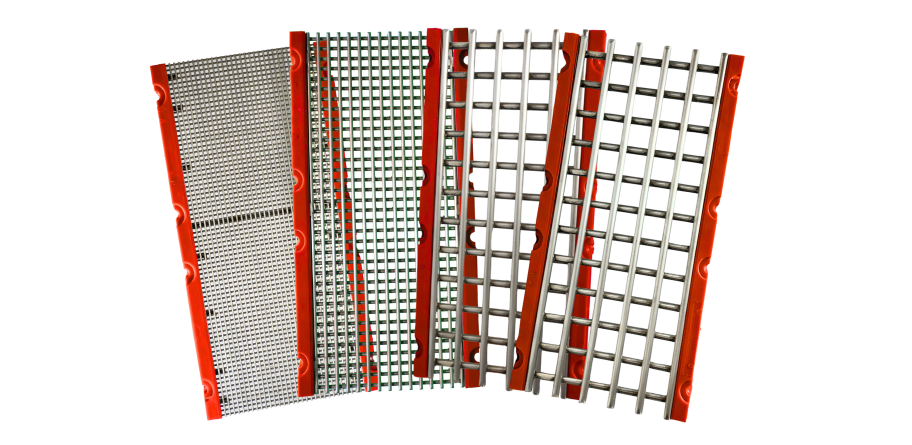

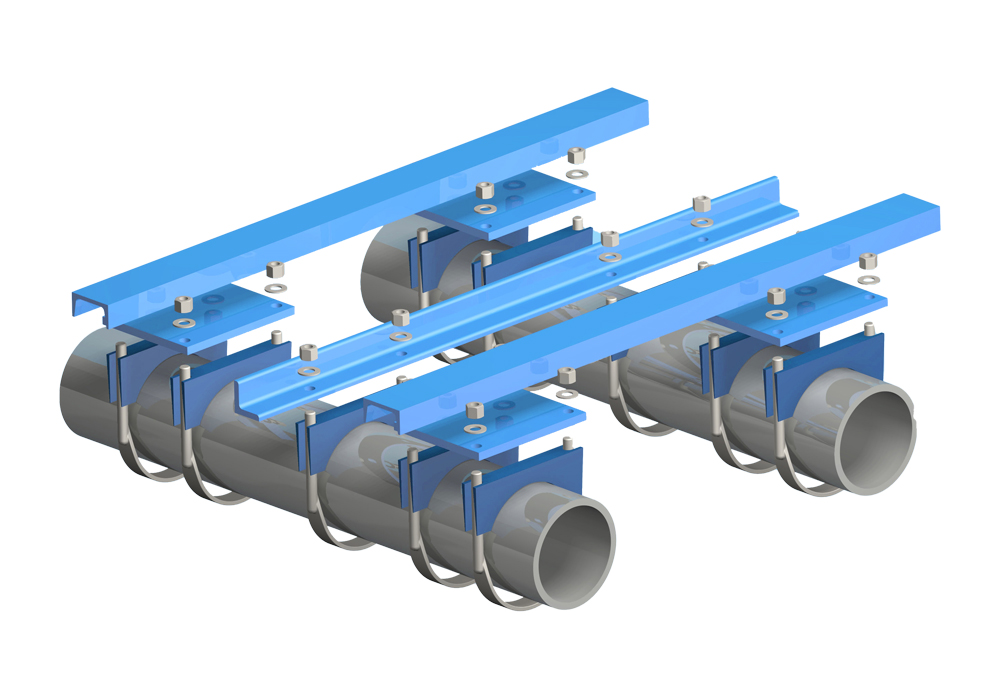

The E-Z Bar system offers flexibility to use a variety of screen media, customized for each unique application.

When it comes to tough applications, Conn-Weld Tuff-Wire brings solutions. Made in our own facility, means a consistent resource of inventory with consistent quality customers can rely on.

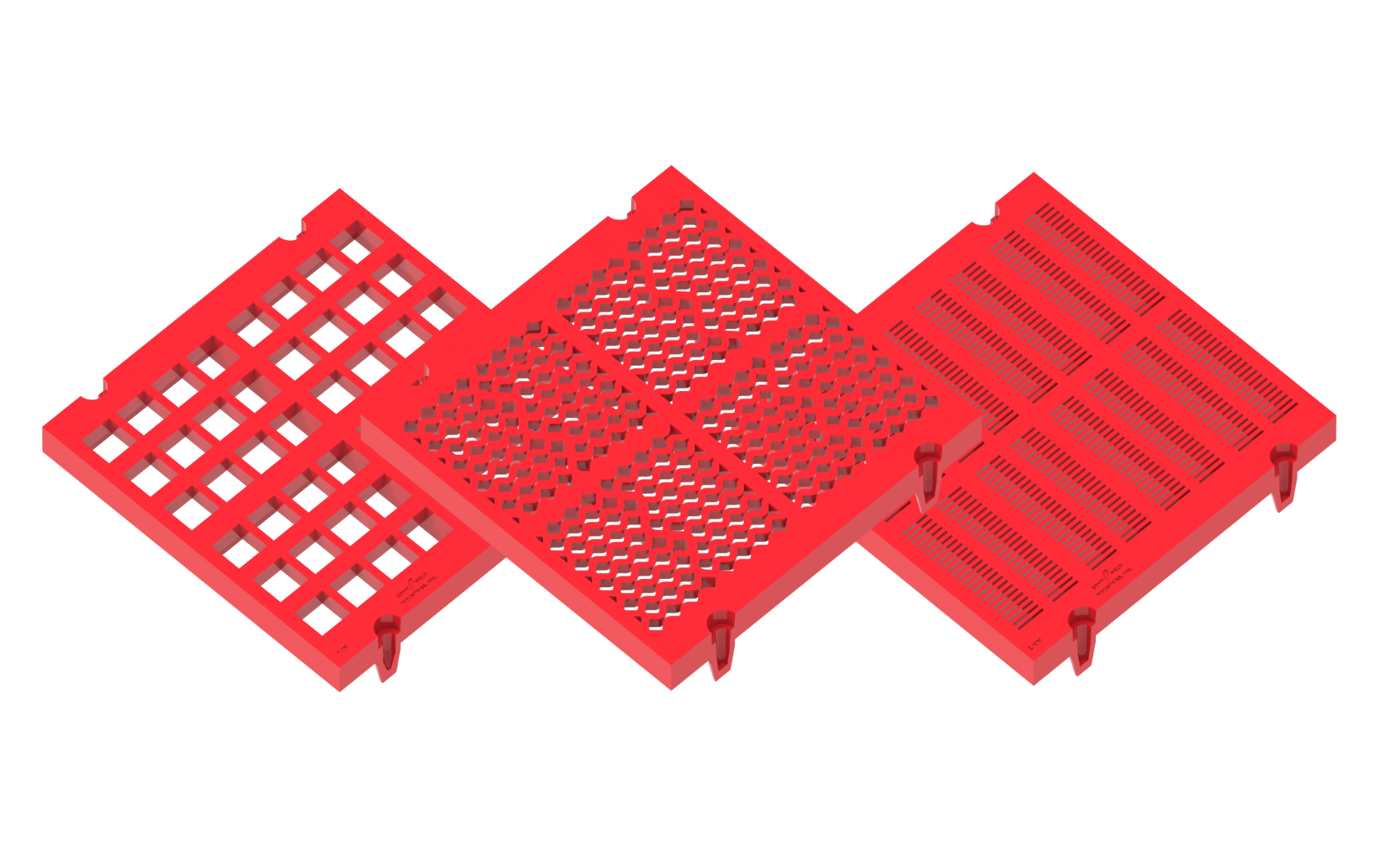

Conn-Weld’s Urethane is made of the highest quality materials in the industry to suit the most abrasive applications, whether wet screening or dry screening.

Conn-Weld has perfected the manufacturing processes of our profile wire and have 50 years of experience when it comes to making sure you have the correct opening and wire size for your specific application.

Conn-Weld’s Perforated Plate brings screening strength and efficiency to our vibrating screens in numerous applications.

Conn-Weld PANELOK systems are easy to install and easier to maintain!

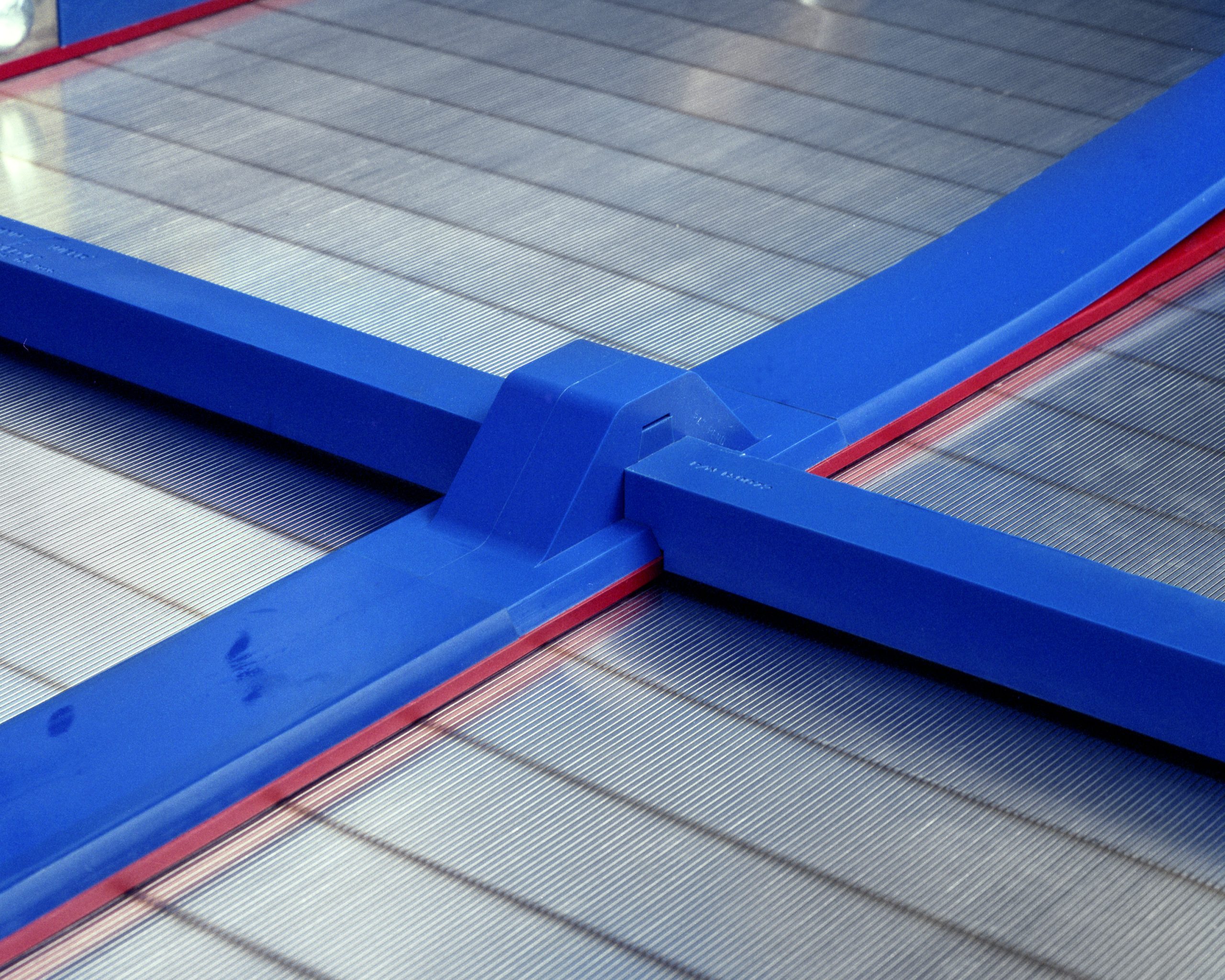

Conn-Weld’s Patented E-Z Deck Frame allows for worn sections to be replaced individually. Designed for easy installation in hard-to-reach places.

Send us a message and a Conn-Weld representative will be in touch within 1-2 business days.

Committed to building our community. Innovating better designs for the real world.