Conn-Weld is a world leader in the development and manufacturing of profile wire shapes. Over 50 years of screen-making experience coupled with our unique fusion-welding process, enables us to furnish the strongest and most reliable welded bar screen-plate technology in the world today.

Coal, Minerals, & Others

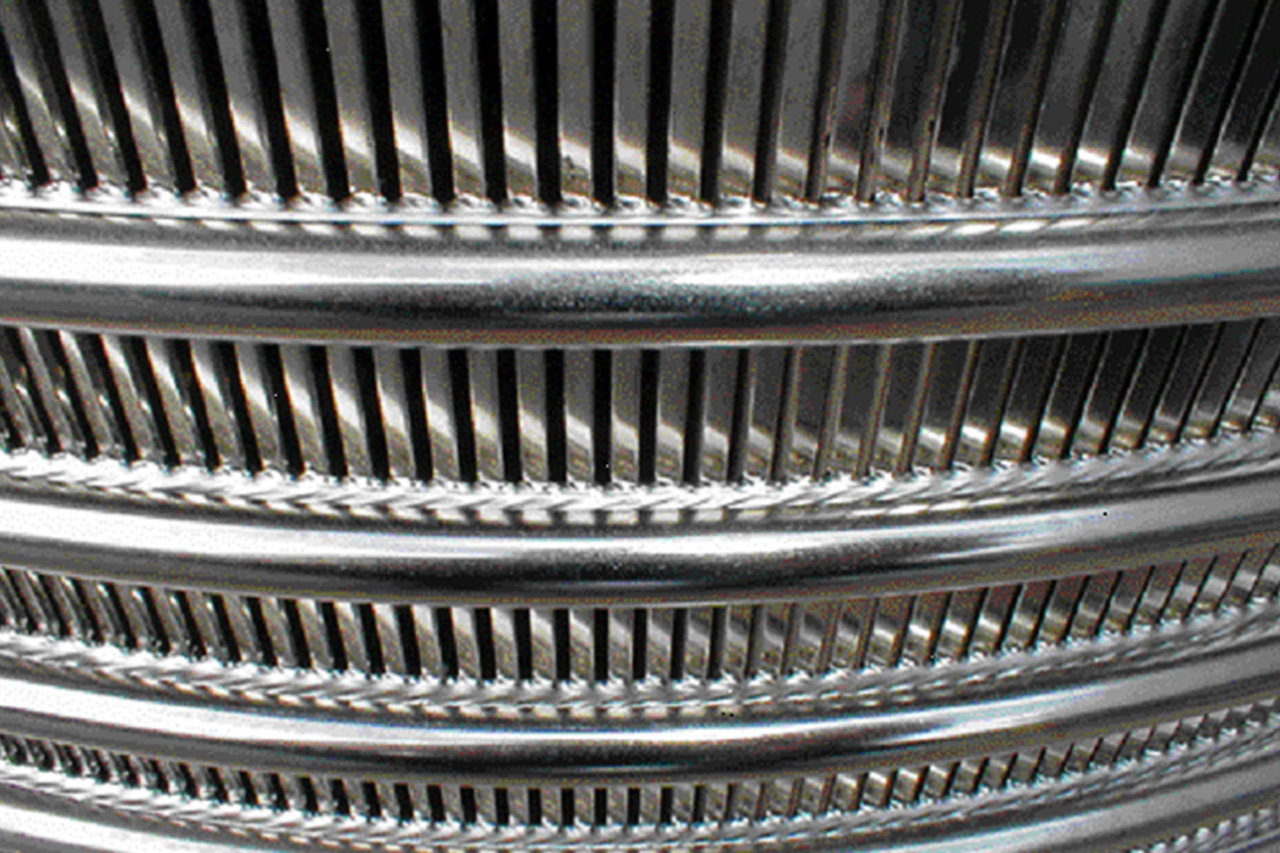

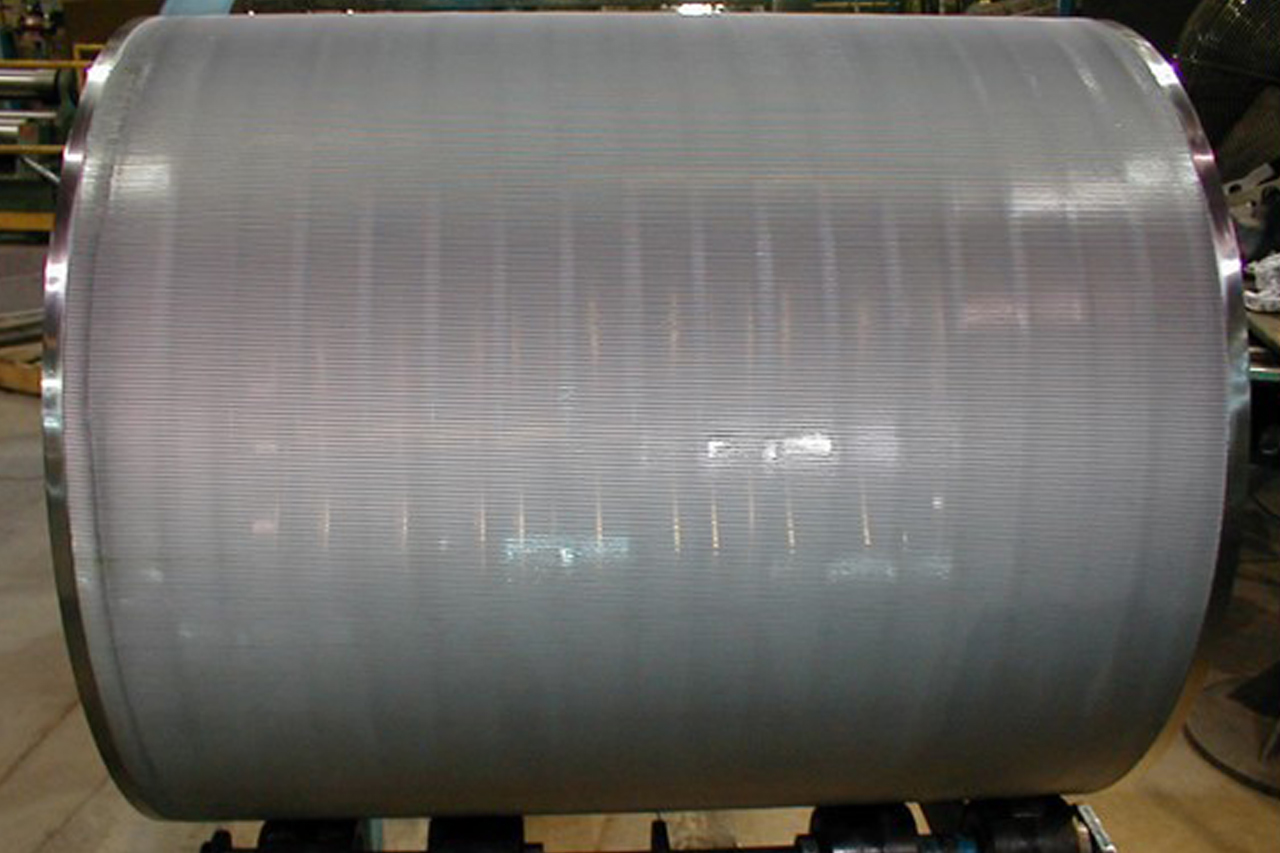

The performance of our full line of centrifuge screens begins with the wire. Through extensive research at our wire plant, we have developed a “high-edge” wire, capable of generating close tolerances and sharp leading edges to break surface tension. This ensures a minimum “break-in” period for the operator.

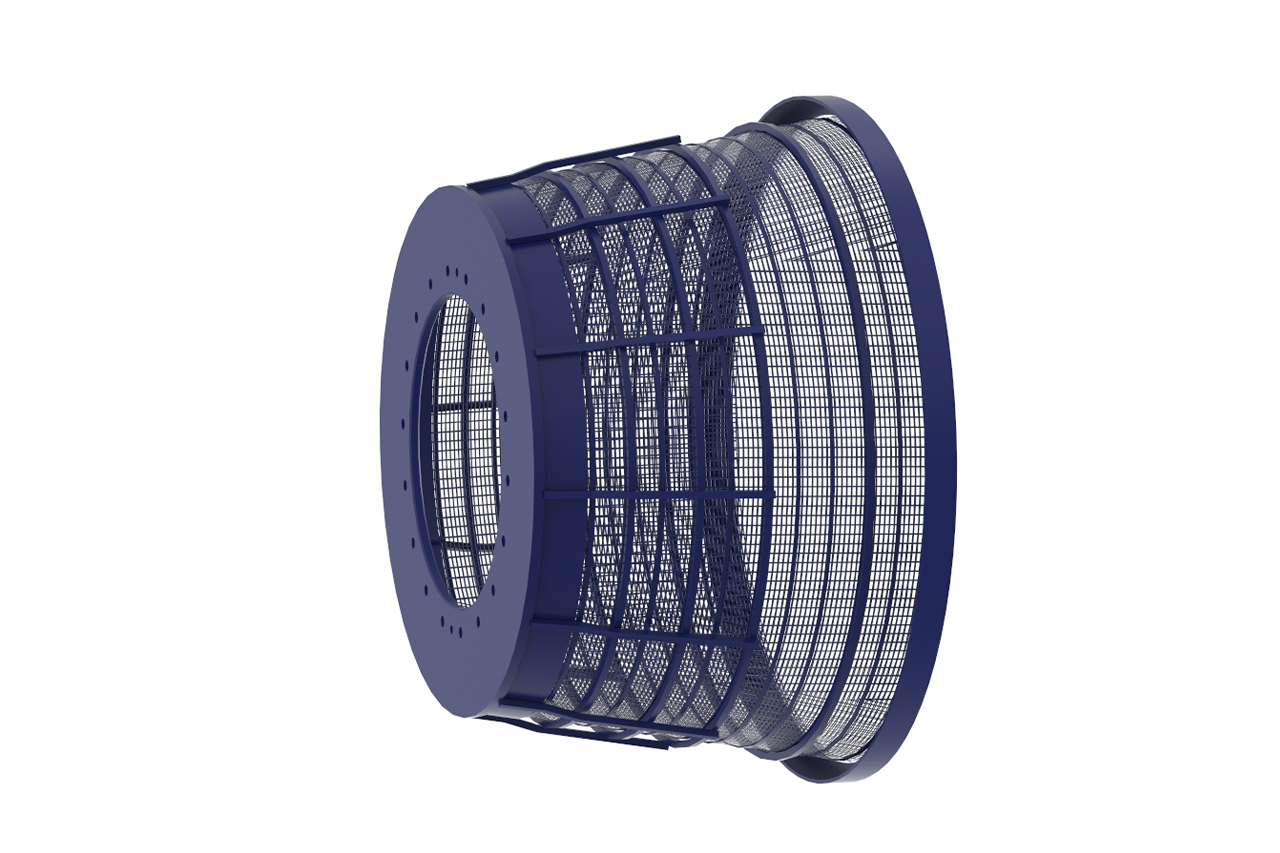

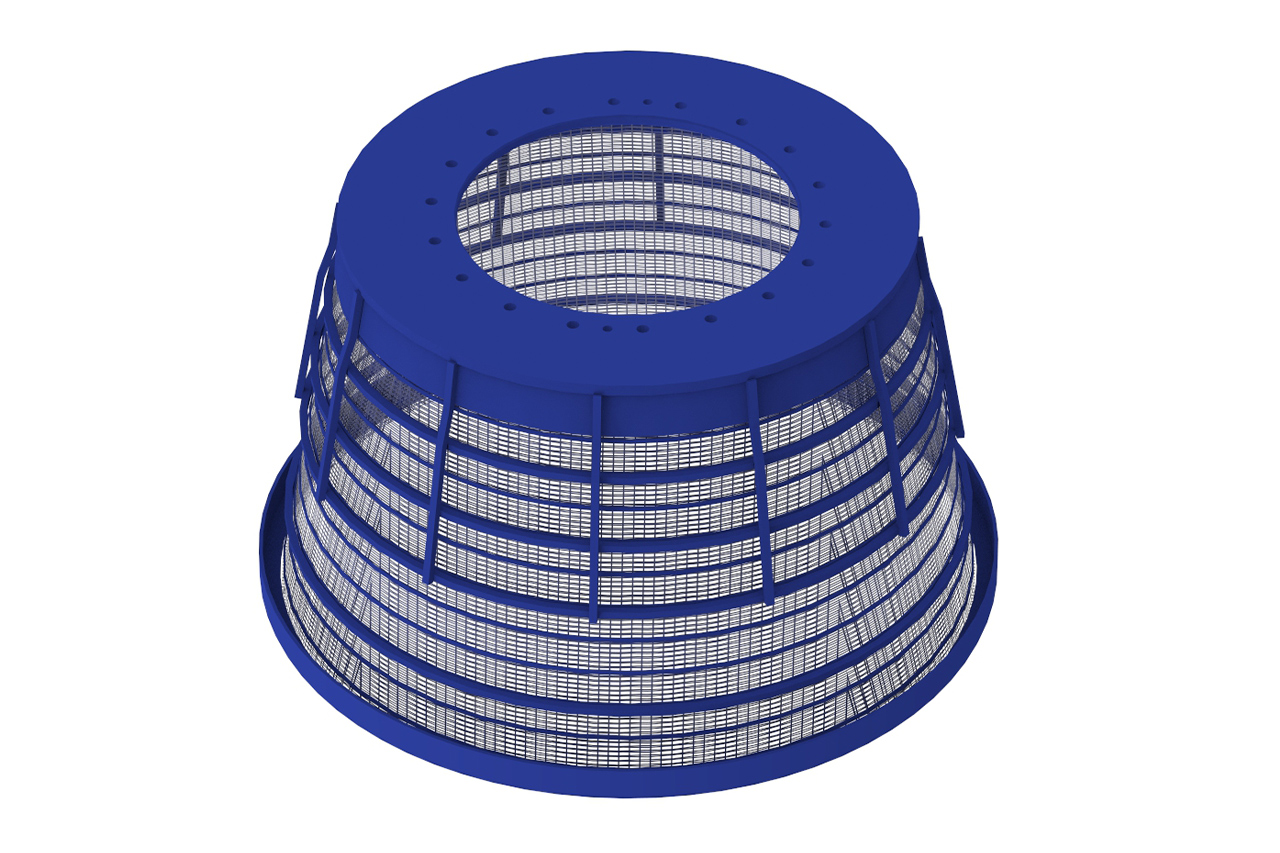

To ensure correct alignment, the screen panels are machine welded to Conn-Weld’s uniquely-designed base and wear ring. The expertly-designed distributors on the interior of the basket spreads the product evenly onto the wear ring and the screen surface to give better dewatering and longer life.

The exterior bracing and outer rings are designed to eliminate weight without sacrificing strength, reducing common torque and load issues the operator may experience, especially during startup and emergency stops. The Centrifuge Screen is dynamically machine balanced to extend the life of the screen, bearings, and entire centrifuge machine

Pulp & Paper

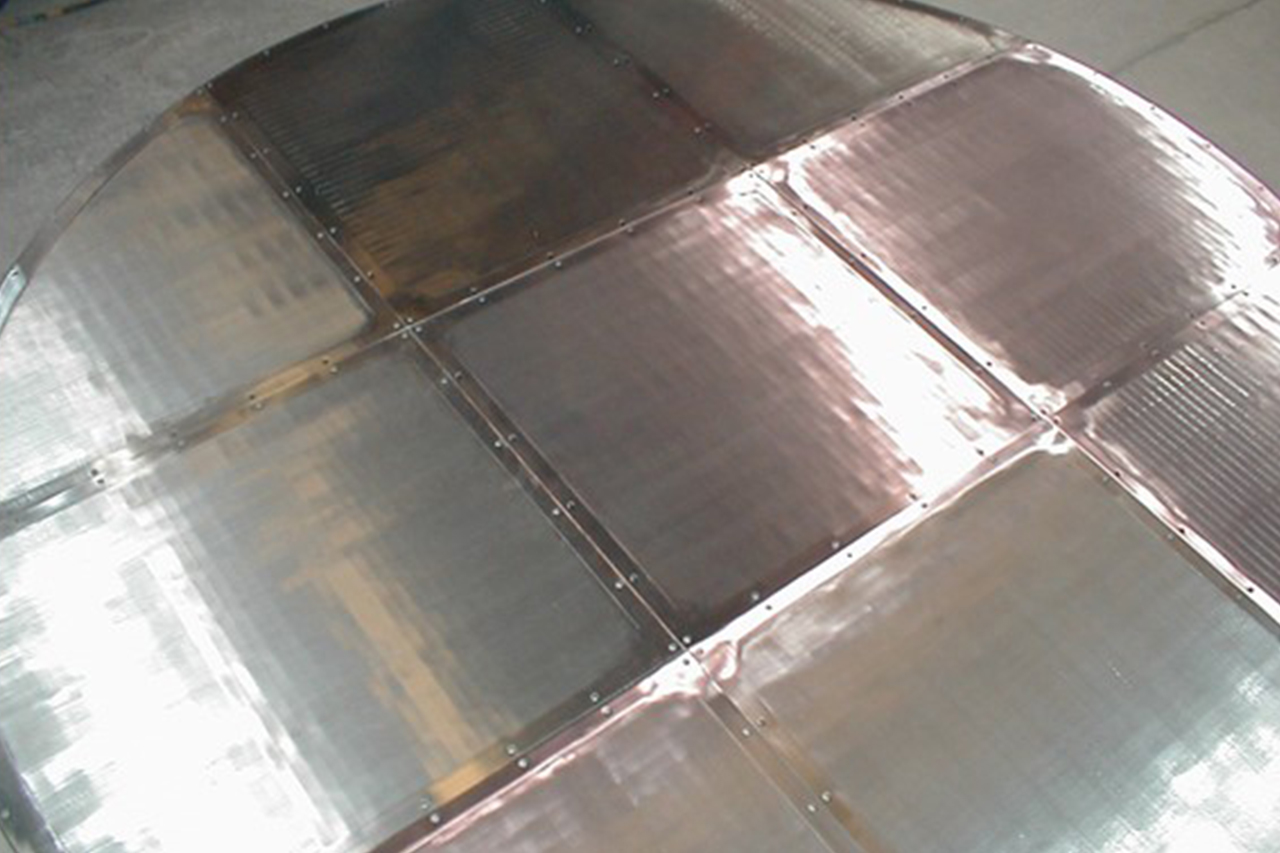

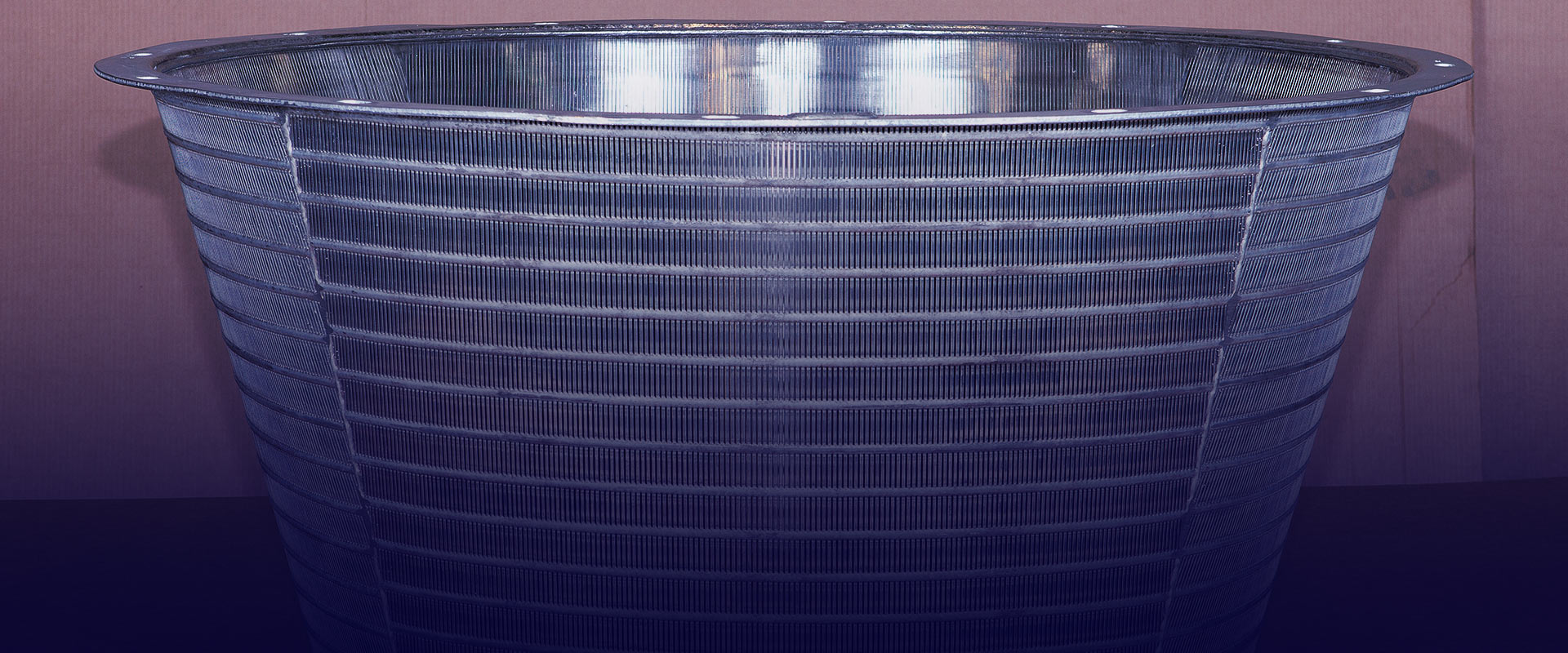

Conn-Weld’s exclusive wedge wire baskets are the most durable in the industry. Utilizing a patented fusion-welding process, Conn-Weld equipment is capable of holding very close tolerances while providing a basket that will stand up to the harsh conditions of pulp, paper, and recycling processes.

In tests, our baskets beat the competition. Conn-Weld’s customers see improved operating efficiency, reduced energy cost, and better overall fiber length and quality. And because of our methods, they experience more control, which yields a more consistent product.

Our experienced engineers partner with you to bring value to your overall operation.

pressure basket close up

custom screen basket

Fill out the fields below to get more information.