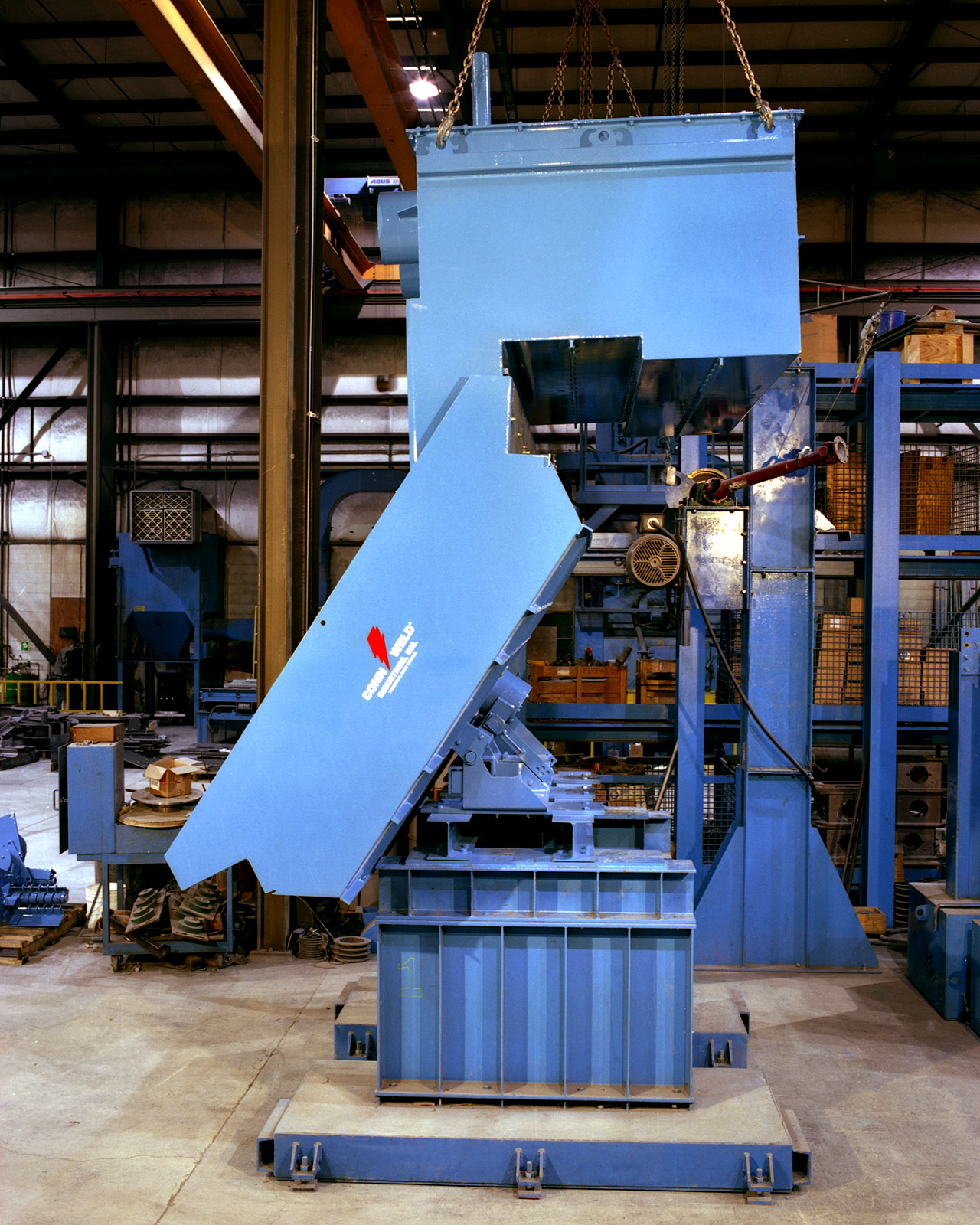

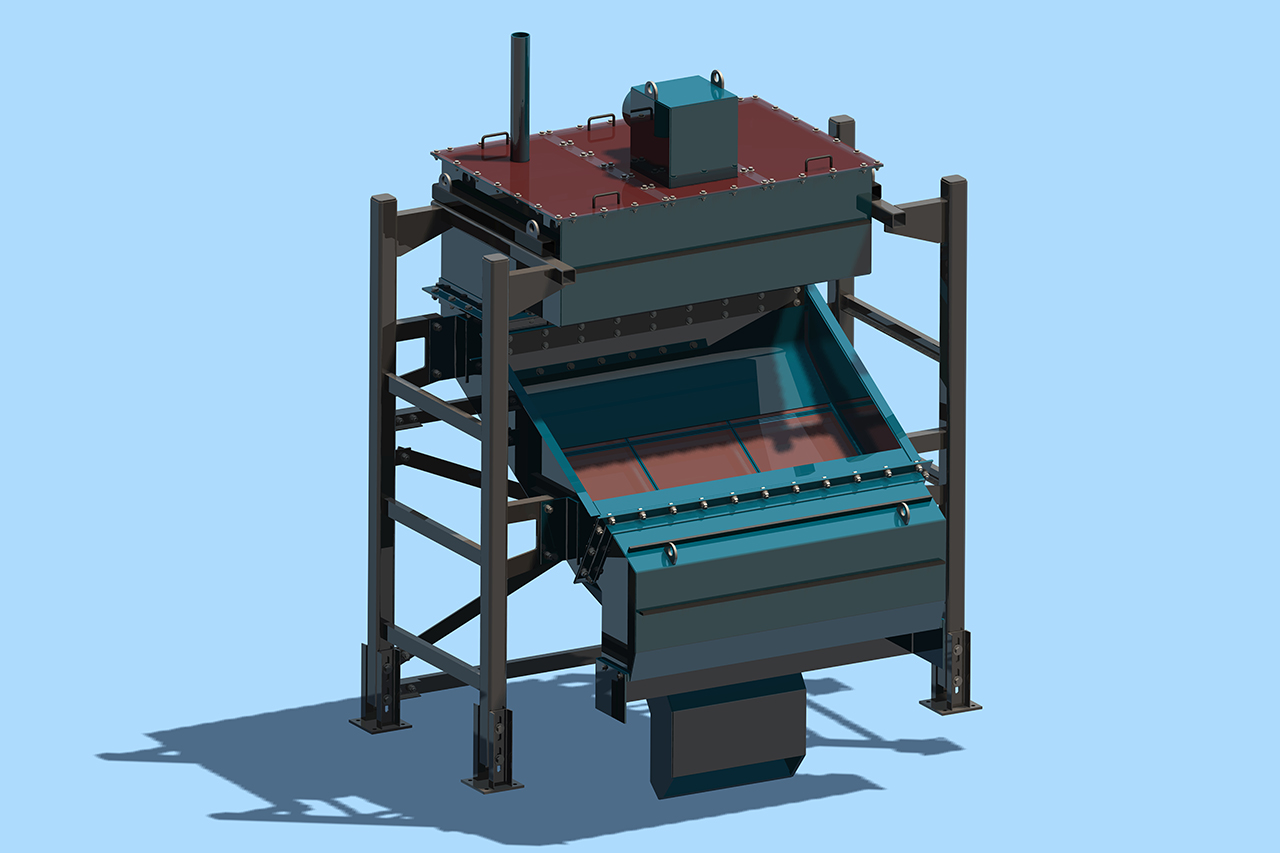

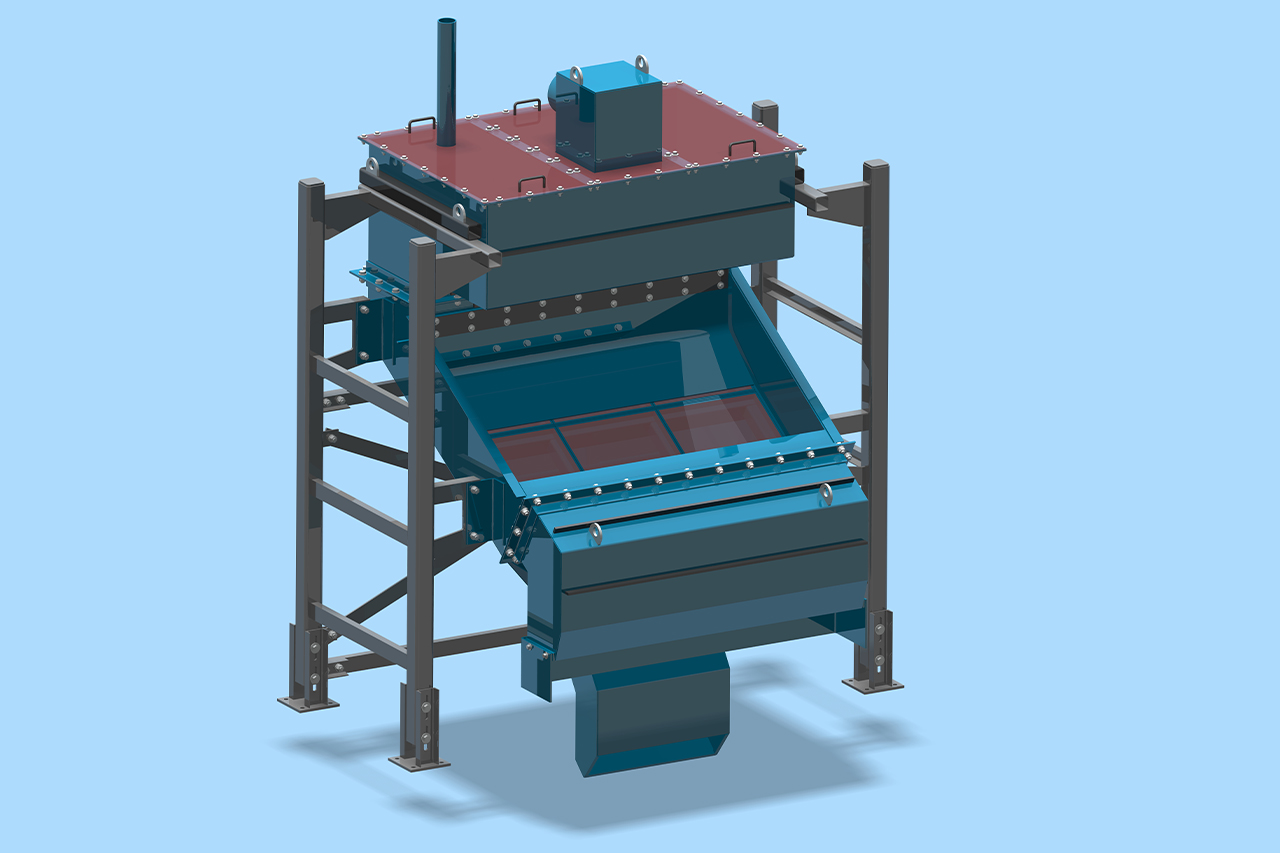

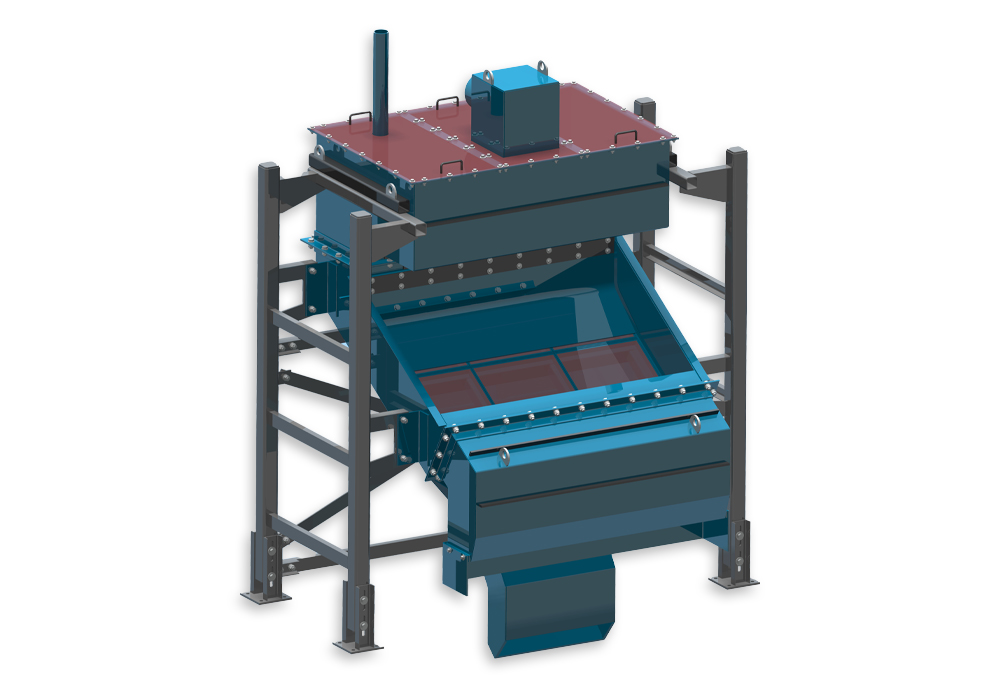

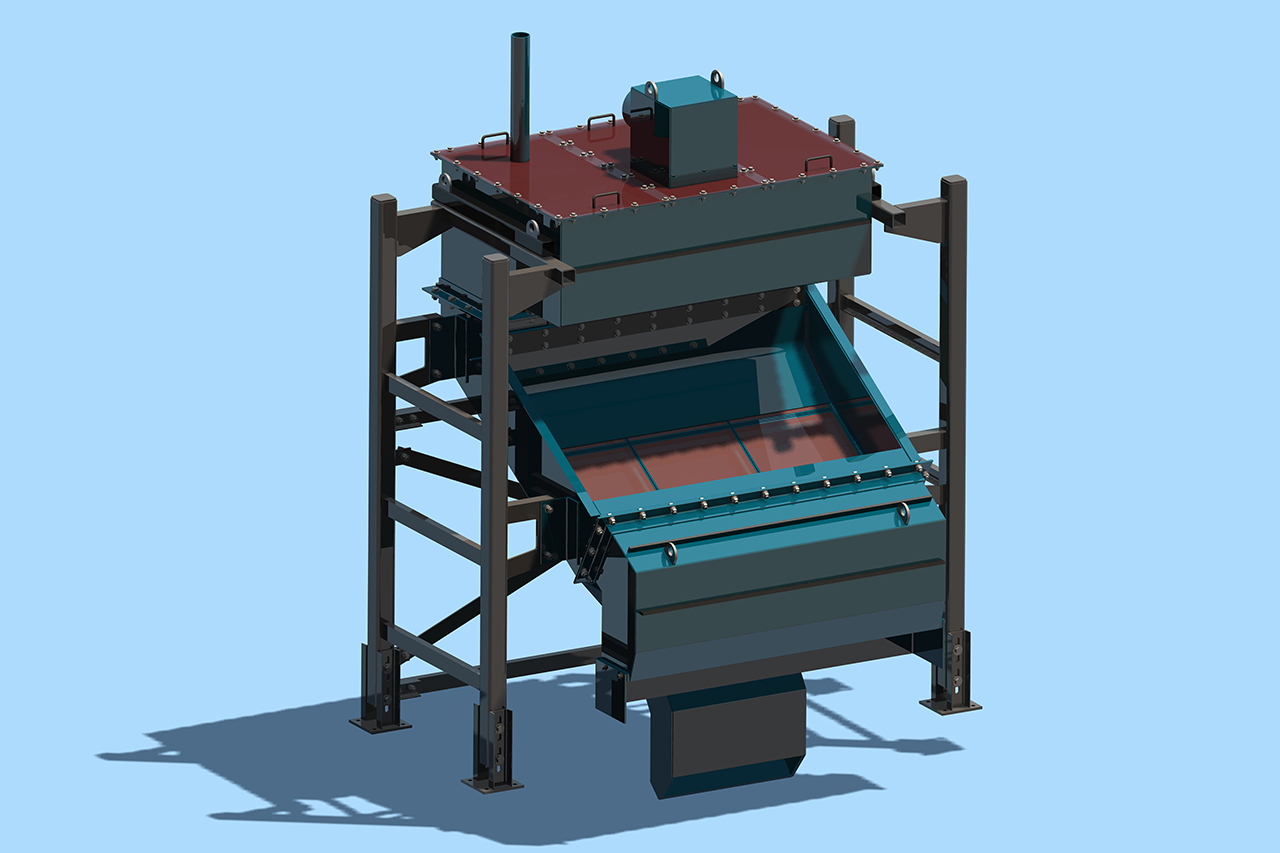

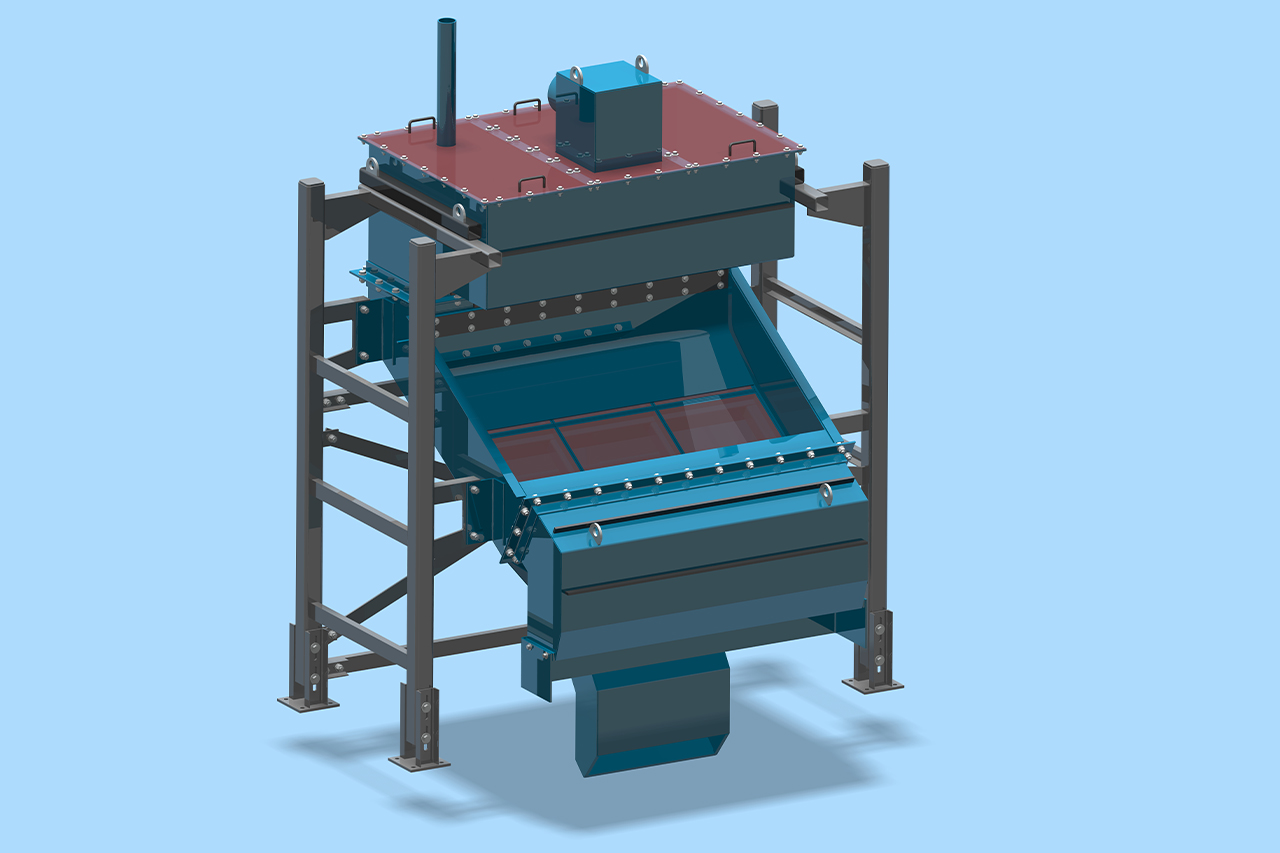

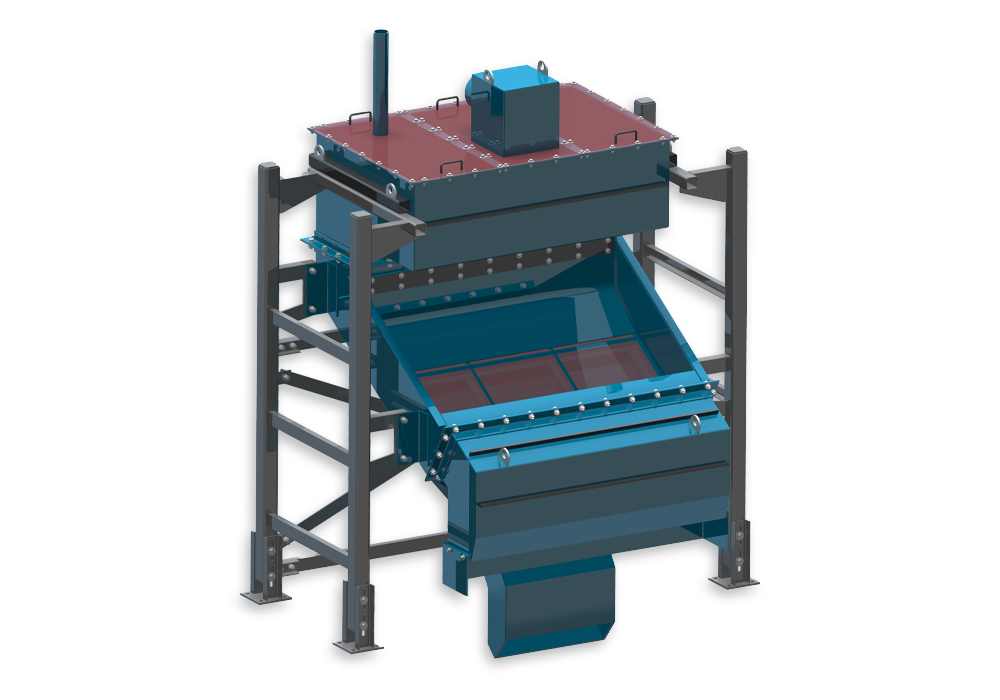

Conn-Weld’s Sieve units are manufactured with high specifications and durable components for maximum uptime and easy maintenance.

Advantages such as the quick reversal turnaround system and adjustable feed gate are proof we listen to the unique requests of our customers.

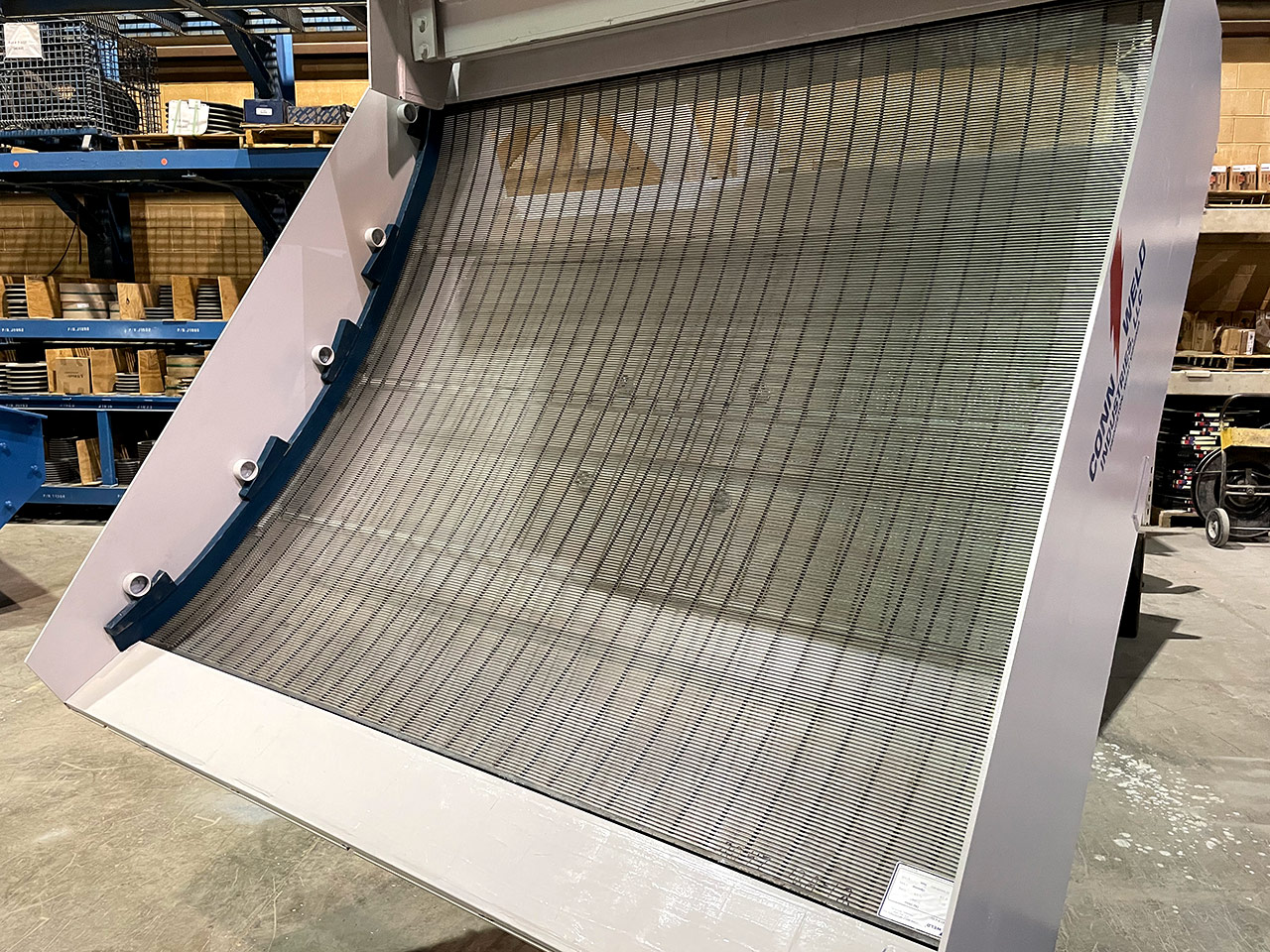

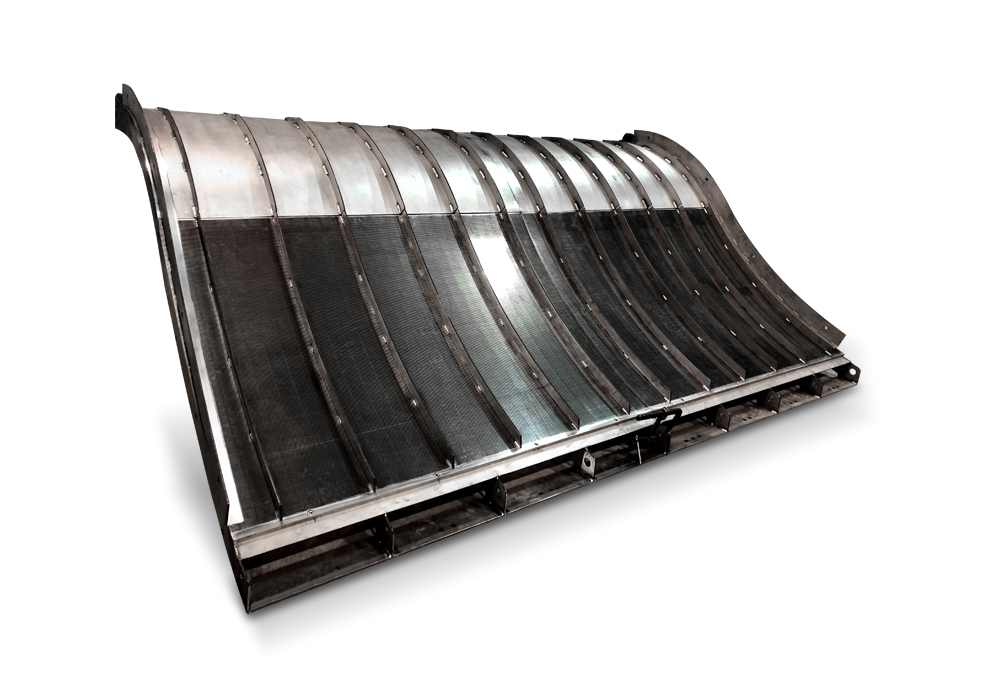

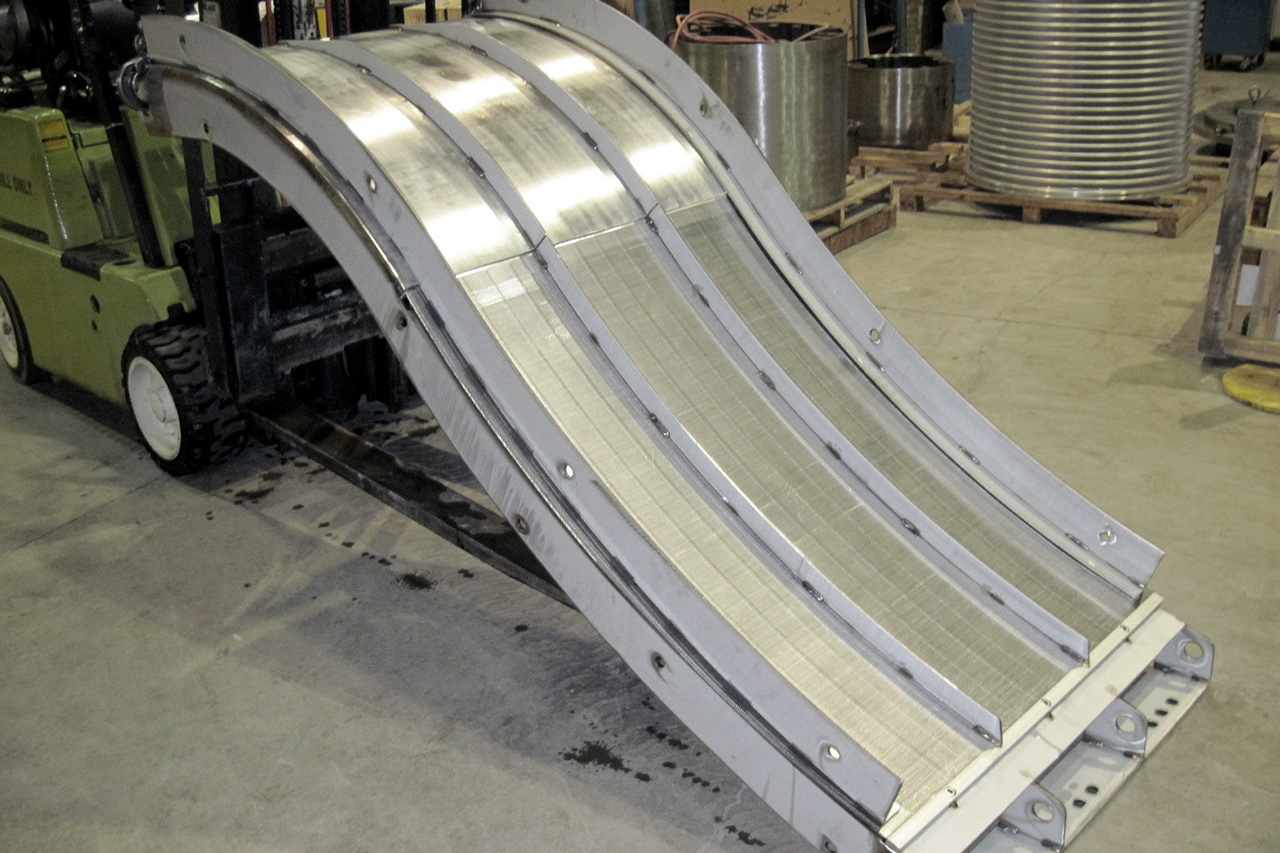

Conn-Weld manufactures the widest range of profile sieve screens in the industry today, with particle separation ranging from 50 microns and up. The profile screen surface has knife-sharp edges for removal of layers of liquid and undersize material as the liquid passes the opening thus preventing blinding of the slot opening. Conn-Weld’s unique Feed Gate is designed so that the operator may adjust and clean the opening to evenly distribute the slurry across the entire width of the screen at right angles to each knife sharp profile wire and slot opening.

Conn-Weld profile sieve screens are manufactured with a sharp cutting edge to slice away the slurry.

Coal, Minerals, Aggregate, Sand & Gravel, Food, Waste Water, & Others

Conn-Weld’s Sieve units are manufactured with high specifications and durable components for maximum uptime and easy maintenance. Advantages such as the quick reversal turnaround system and adjustable feed gate are proof we listen to the unique requests of our customers.

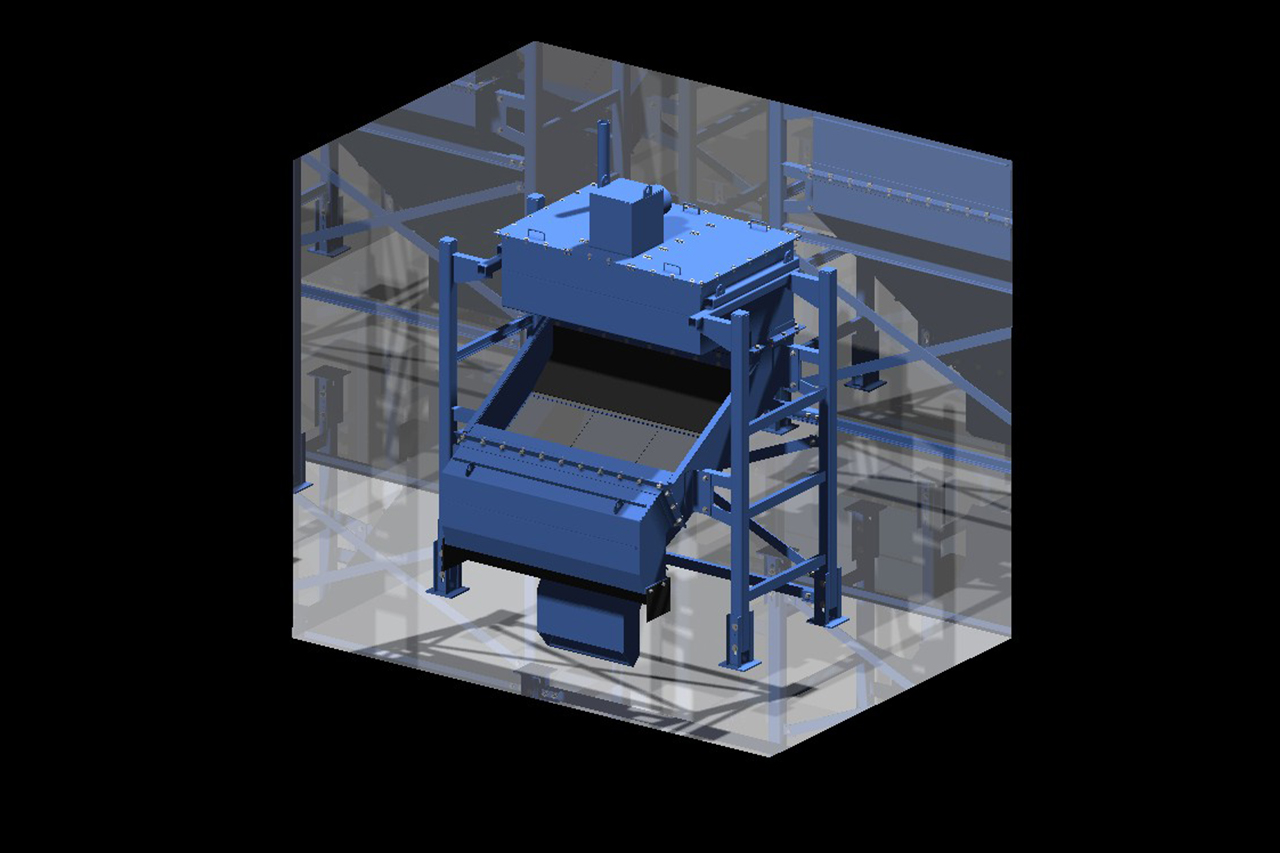

Banana Style Vibrating Screen

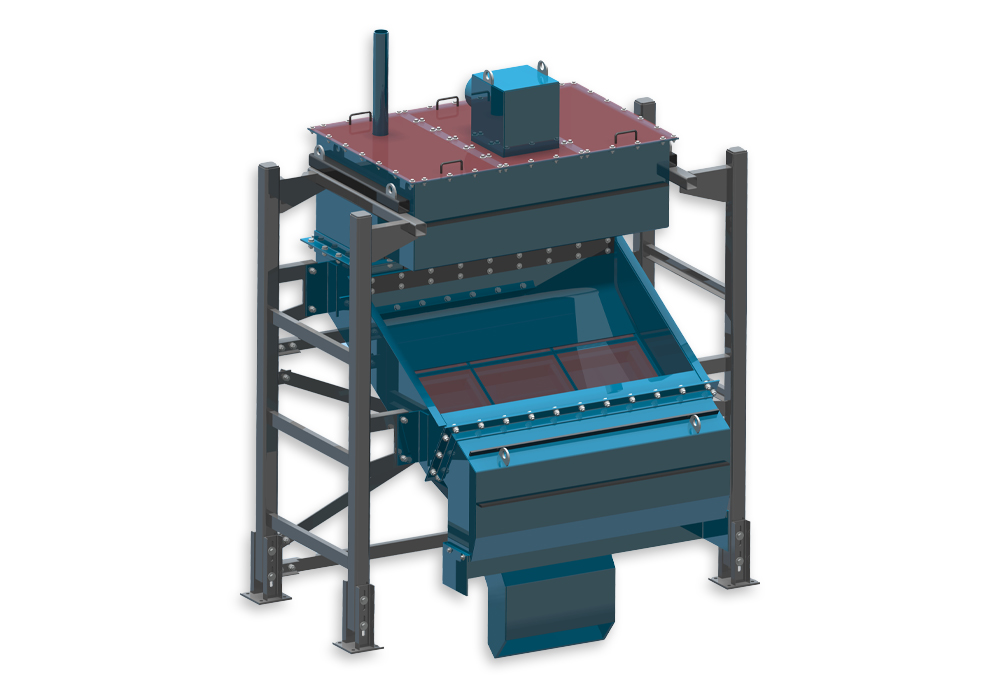

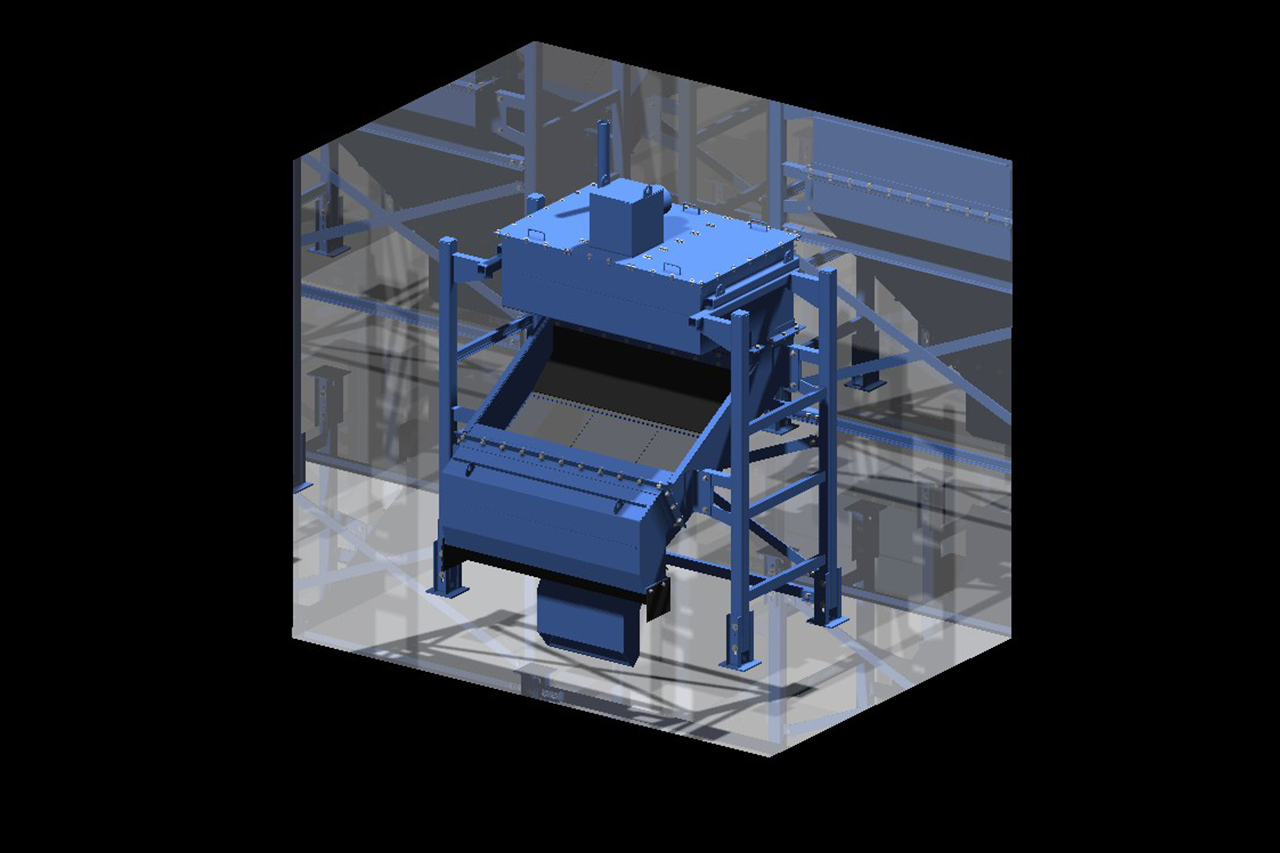

Curved Sieve

Curved Sieve

Curved Sieve

Curved Sieve

Screen Basket

Curved Sieve

Curved Sieve

Curved Sieve

Coal, Minerals, Aggregate, Sand & Gravel, Food, Waste Water, & Others

fixed flat sieve ahead of vibrating screen

fixed flat sieve

fixed flat sieve

fixed flat sieve

Hydro Power & Water Treatment

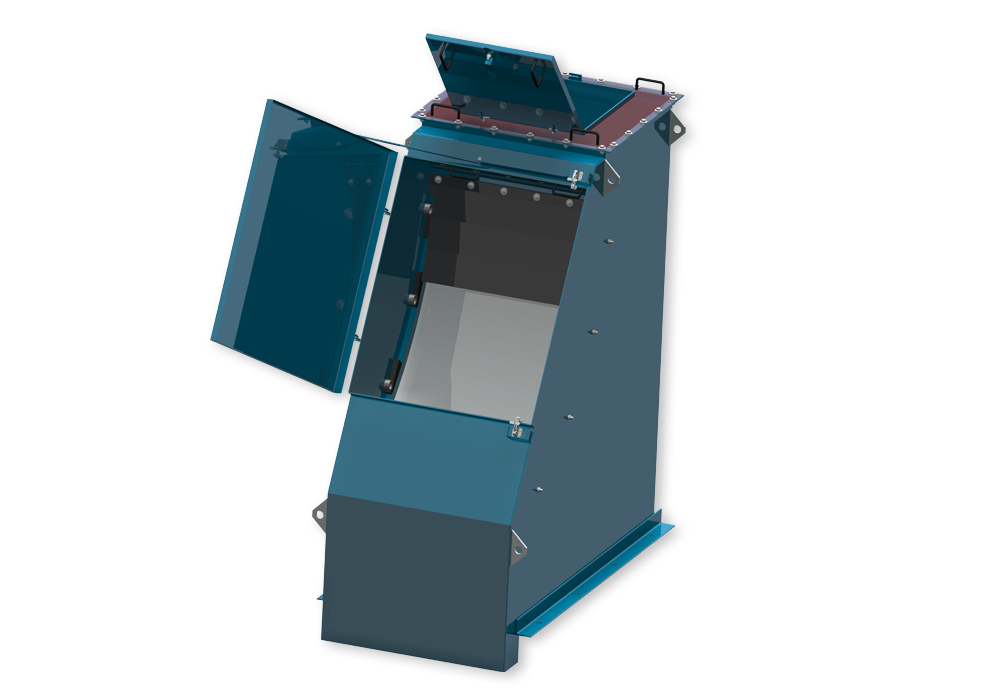

A “green solution” for water treatment applications, Hydro-Sieve is an efficient sieve using proven technology to screen out sediment and aquatic life. Conn-Weld uses tilted wedge wires to create a cutting action on the upstream sides of the wires that greatly enhance throughput over traditional wedge wire screens.

Hydro-Sieve can screen particles to 60 mesh and for heavy-duty needs, we can add grizzly protection ribs to protect the sieve during floods. Features like our unique flow relief gate reduce discharge flow barriers which can cause splashing and icing during cold months.

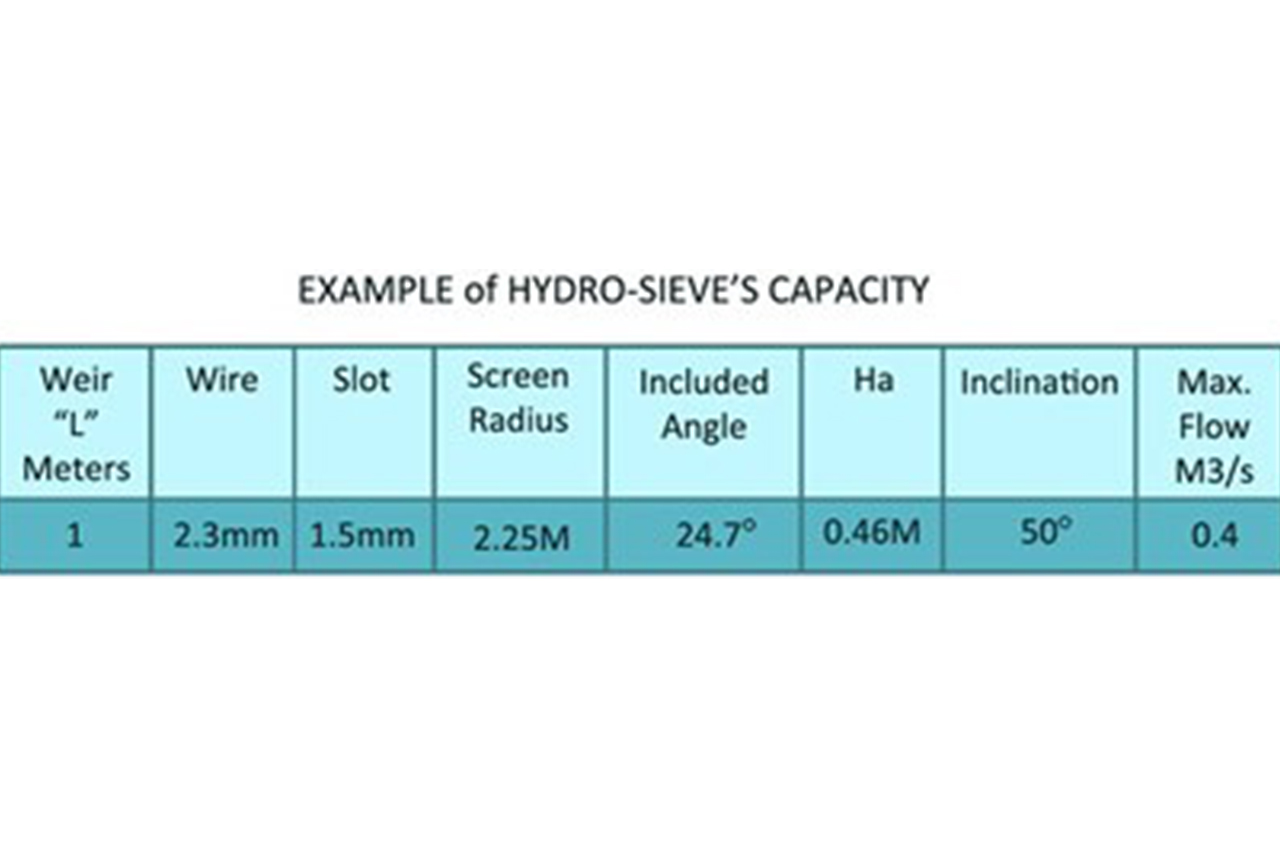

HYDRO-SIEVE CAPACITY

Flow through a Hydro-Sieve is based on several factors; screen open area, orifice flow, shearing flow, velocity head, accelerator plate elevation drop (Ha) and approach channel “p” height. Once we have your project data we can determine the maximum throughput and address other design considerations such as debris loading, flooding, and aquatic life concerns.

hydro sieve

hydro sieve

hydro-sieve

hydro sieve

Pulp & Paper, Food, Minerals, Corn Screening, Coal

fixed flat sieve ahead of vibrating screen

fixed flat sieve

fixed flat sieve

fixed flat sieve

fixed flat sieve

Fill out the fields below to get more information.