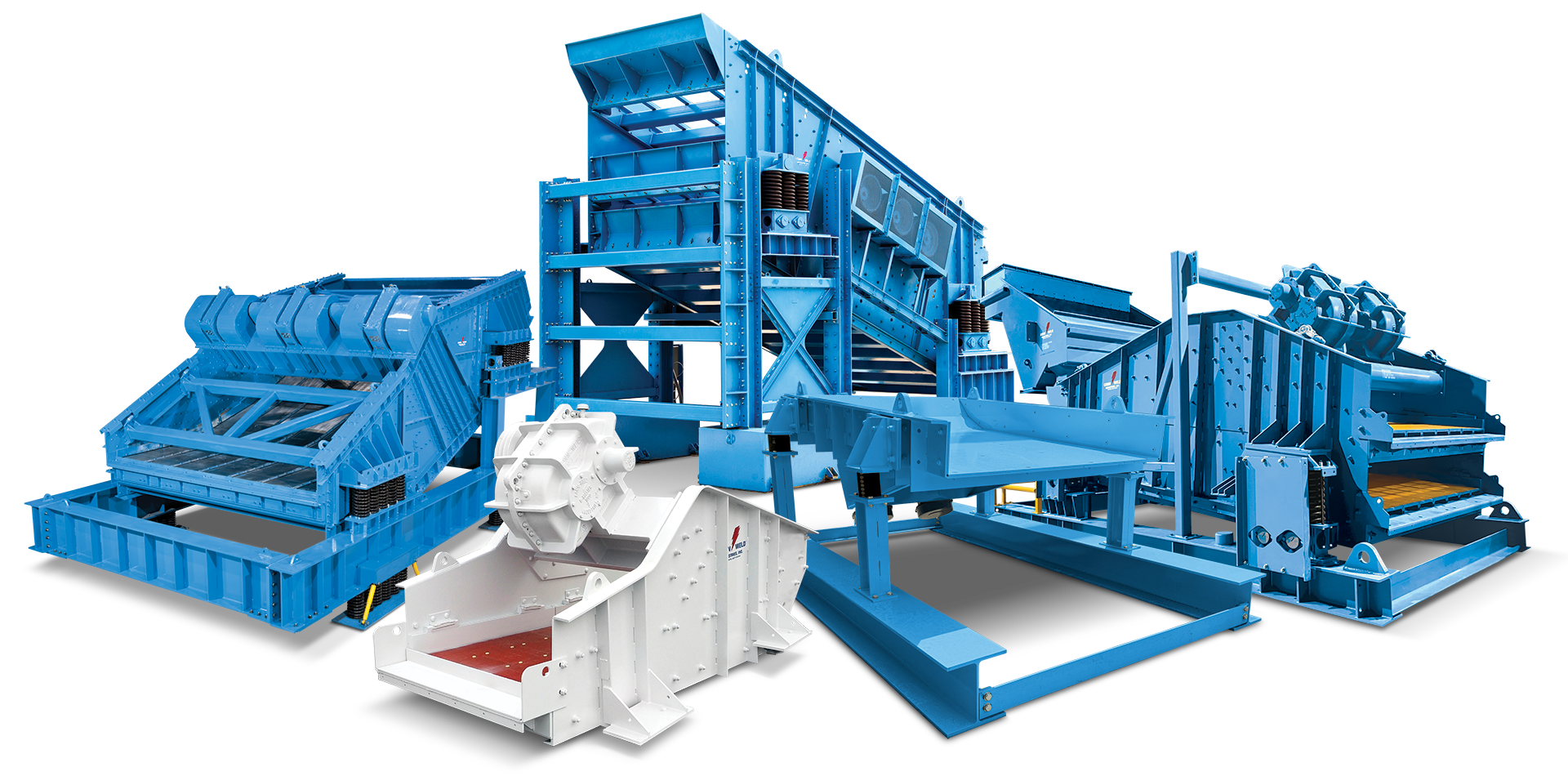

With our unique and custom designed high-quality products, we help our customers save engineering time and cost while improving their operational efficiency.

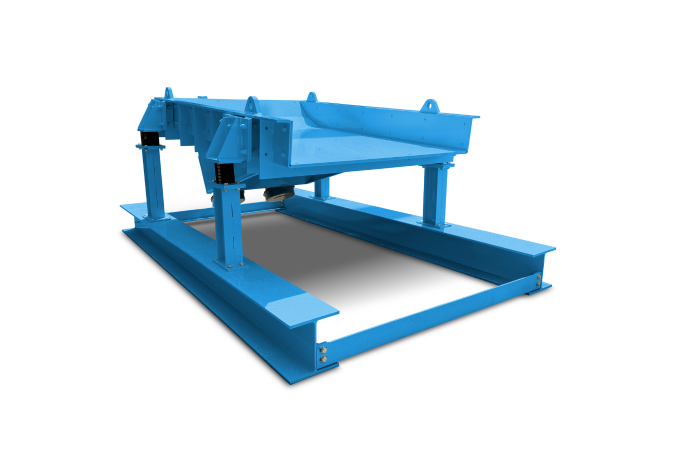

The Conn-Weld Elliptical Horizontal speaks to years of dedication for innovative solutions in unique challenges.

Conn-Weld’s High-Frequency Dewatering Screens are designed to handle the toughest challenges in screening – dewatering.

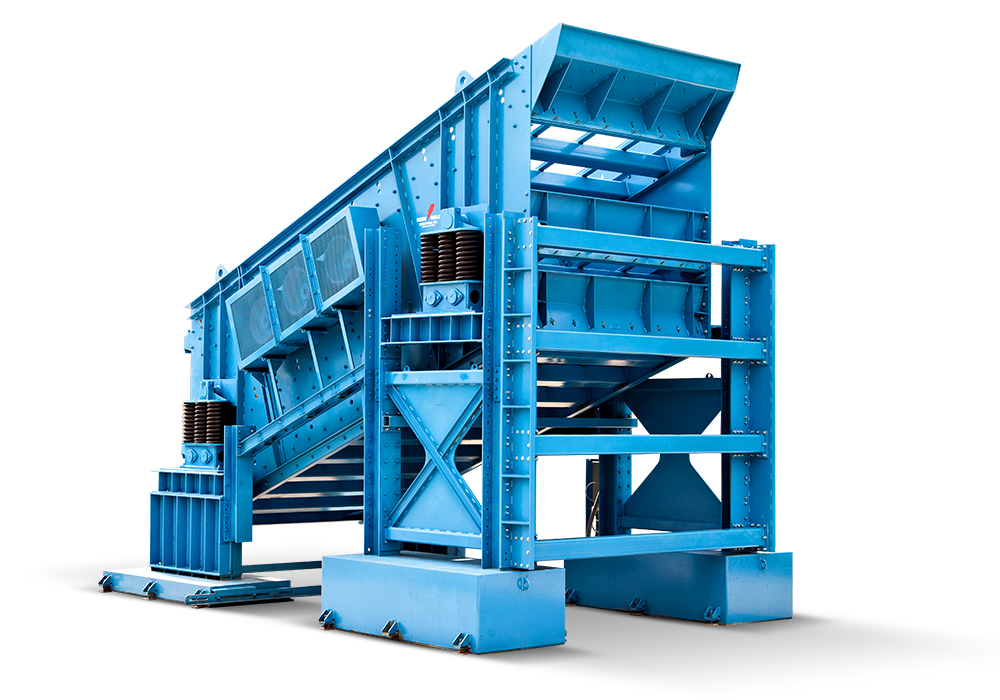

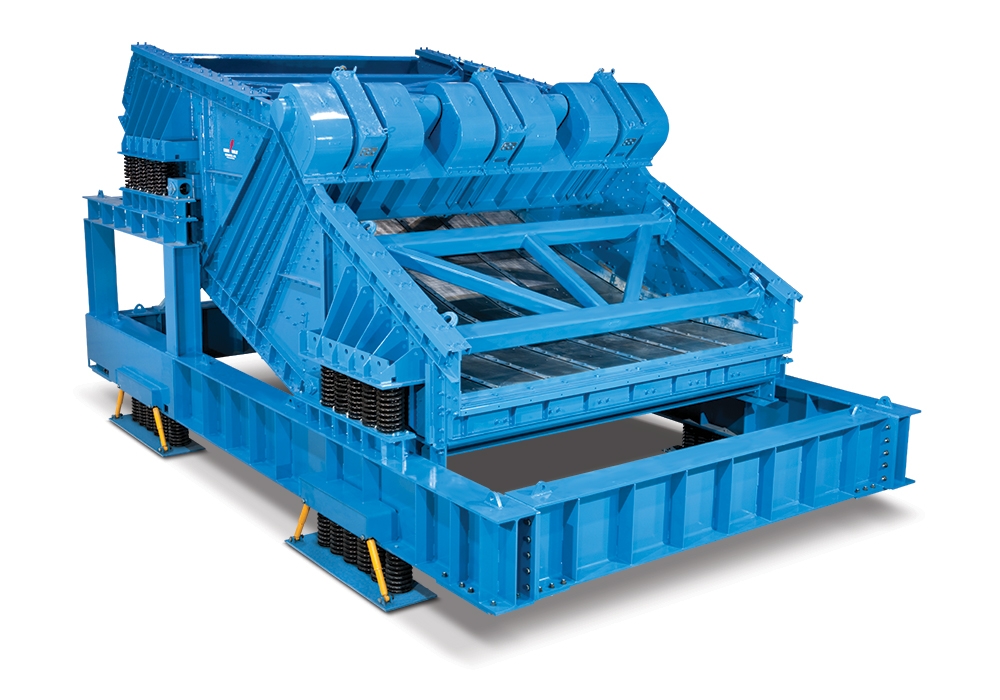

Conn-Weld’s Extreme Duty Scalping Screens stand up to the most demanding applications and large tonnages.

Conn-Weld Incline Screens are designed for numerous applications, from primary scalping to finishing wash screens.

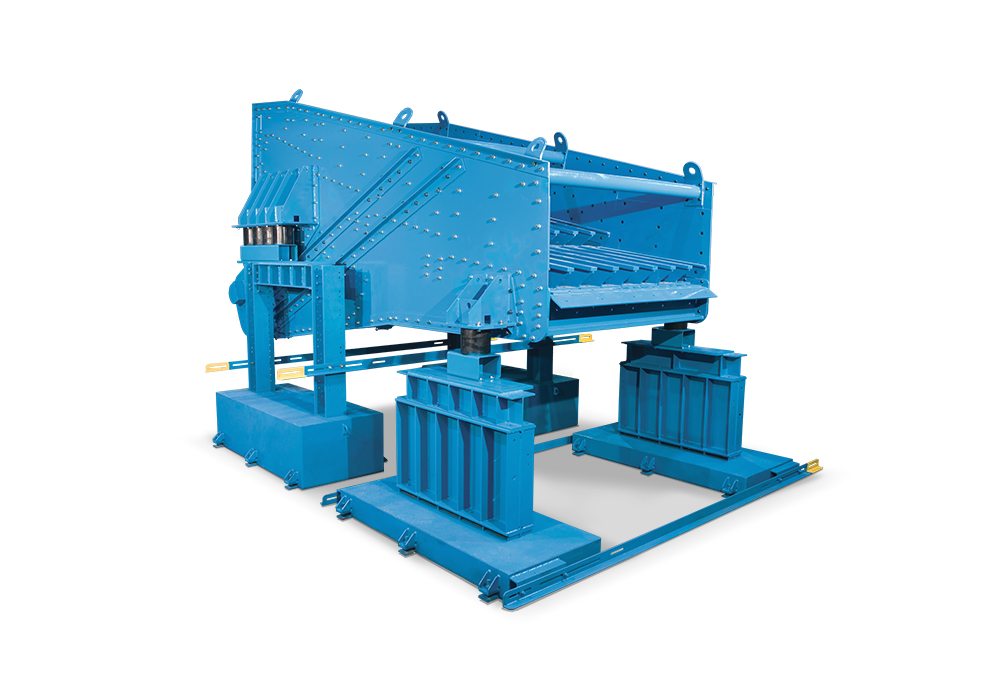

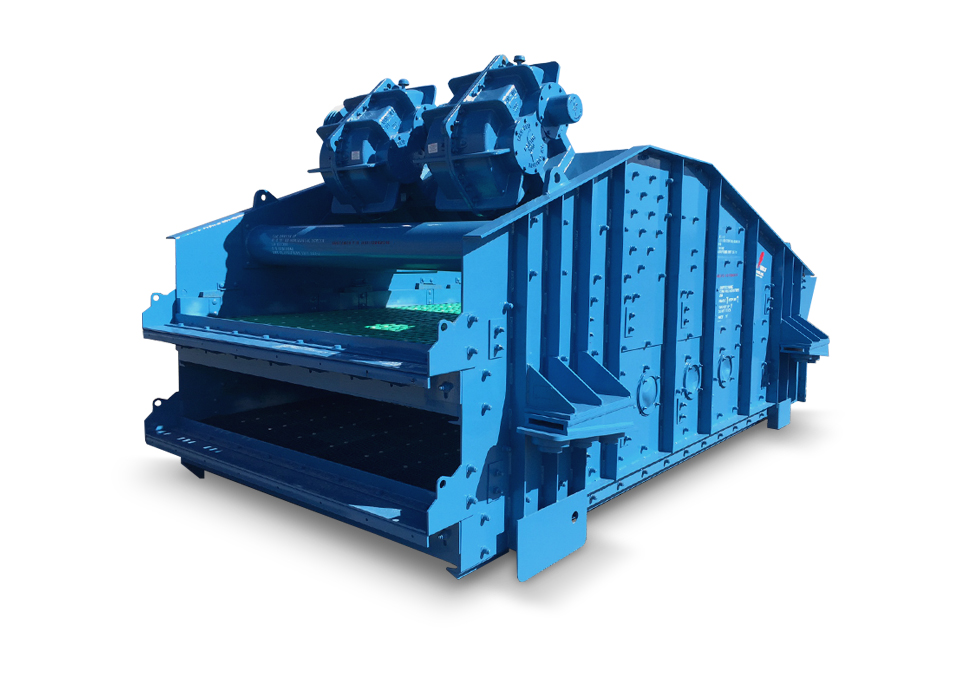

Conn-Weld’s Horizontal Screens have proven performance in every application.

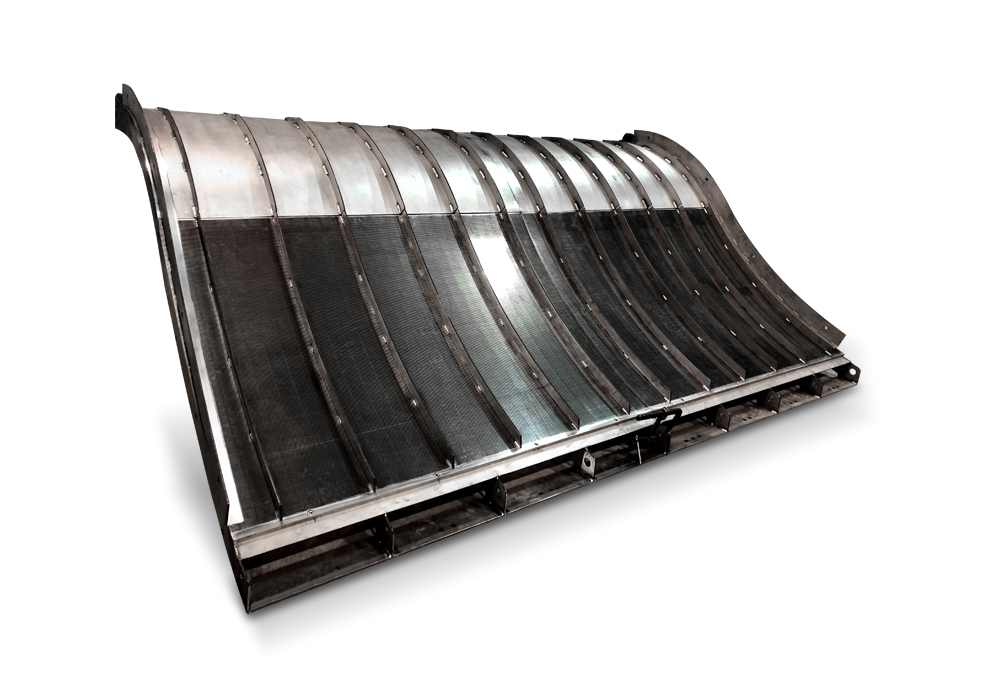

Conn-Weld’s Banana Style Screens offer superior quality and high-capacity screening. To ensure proper fit, we pay close attention to every unique request.

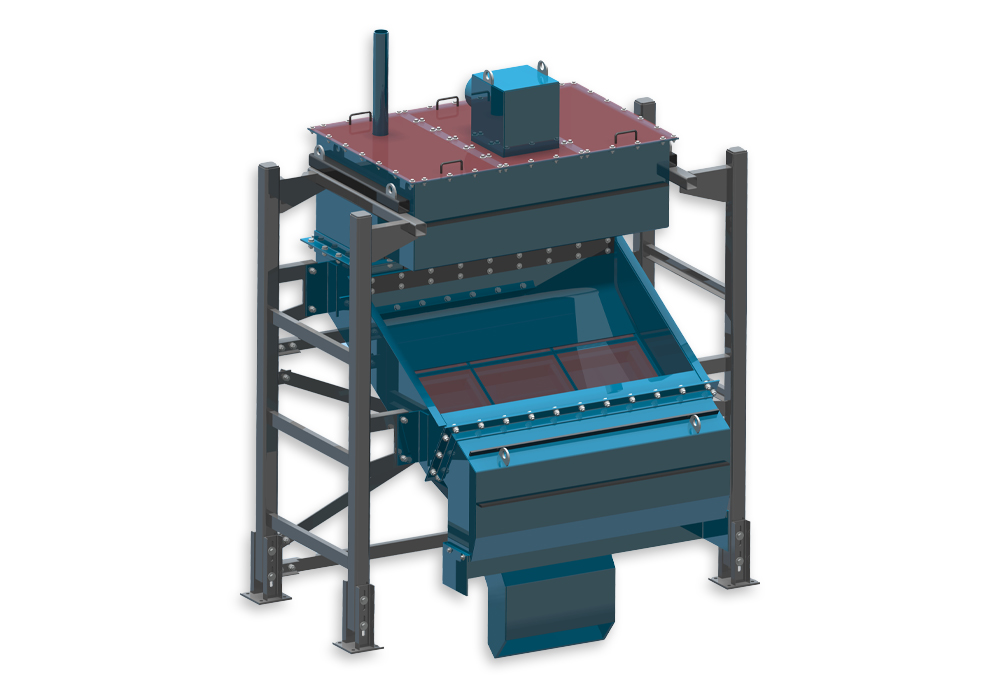

Conn-Weld’s Sieve units are manufactured with high specifications and durable components for maximum uptime and easy maintenance. Advantages such as the quick reversal turnaround system and adjustable feed gate are proof we listen to the unique requests of our customers. Particle separation ranging from 50 microns and up. Profile sieve screens a...

Static operations Typically upstream of a Vibrating Screen for most efficient slurry cut and recovery while feeding the Vibrating Screen in a laminar fashion. With Flow applications extends wear life of screens Lower operating costs compared to Curved Sieve Higher capacity than conventional Sieve Units Standardized screen panel to common sizes Can...

A “green solution” for water treatment applications, Hydro-Sieve is an efficient sieve using proven technology to screen out sediment and aquatic life. Conn-Weld uses tilted wedge wires to create a cutting action on the upstream sides of the wires that greatly enhance throughput over traditional wedge wire screens. Hydro-Sieve can screen partic...

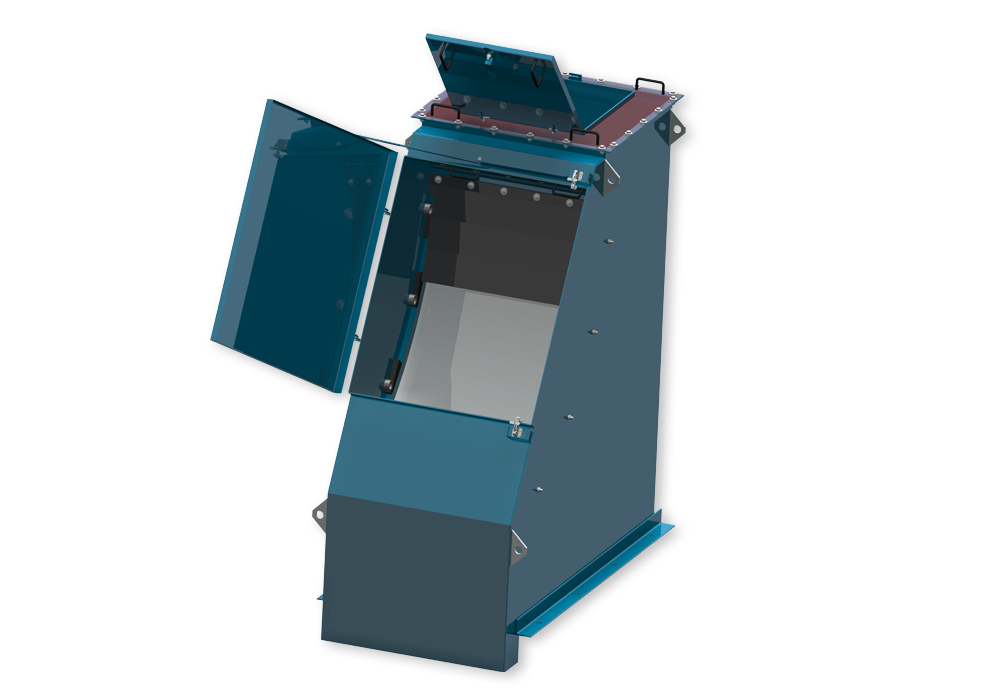

A fully customizable, self-contained unit. Can be pressurized or open/vented to atmosphere Cross Flow application Can be gravity fed or pump fed Adjustable feed gate

The performance of our full line of centrifuge screens begins with the wire. Through extensive research at our wire plant, we have developed a “high-edge” wire, capable of generating close tolerances and sharp leading edges to break surface tension. This ensures a minimum “break-in” period for the operator.

To ensure correct align...

Conn-Weld’s exclusive wedge wire baskets are the most durable in the industry. Utilizing a patented fusion-welding process, Conn-Weld equipment is capable of holding very close tolerances while providing a basket that will stand up to the harsh conditions of pulp, paper, and recycling processes.

In tests, our baskets beat the competitio...

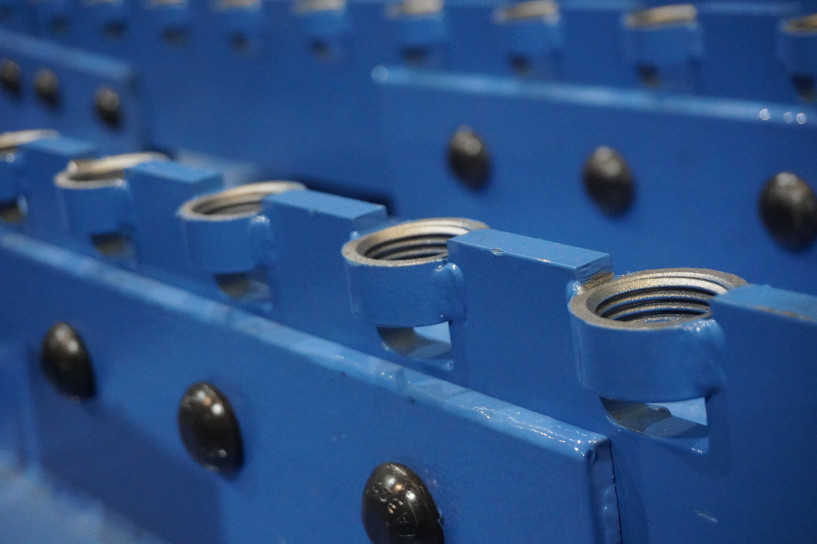

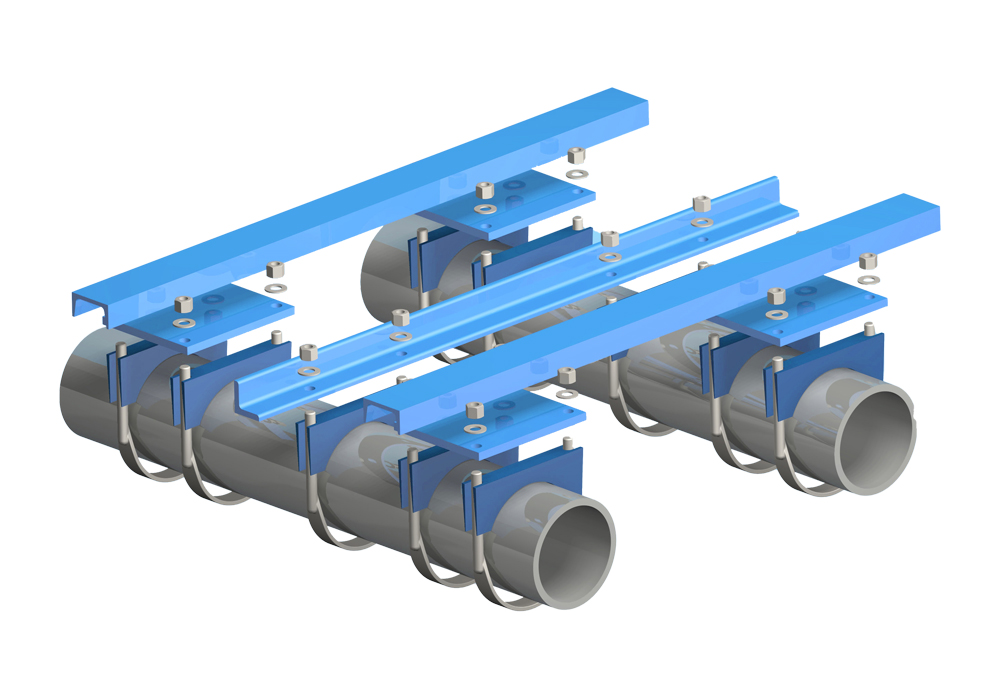

Individual Crossmembers allow for replacing parts as they wear.

Conn-Weld’s Urethane is made of the highest quality materials in the industry to suit the most abrasive applications, whether wet screening or dry screening:

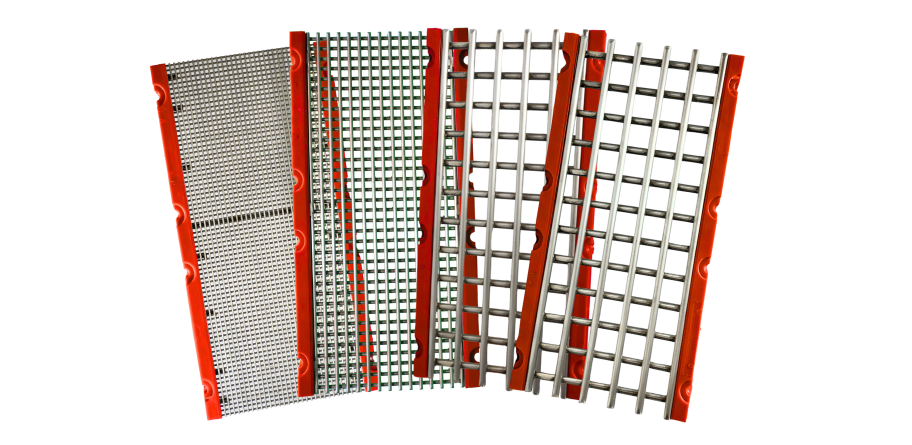

Conn-Weld’s exclusive Fusion Welding Process & Forge Welding Process known as Tuff-Screens®, provide reliable wire support.

Conn-Weld has perfected the manufacturing proc...

Conn-Weld’s Perforated Plate brings screening strength and efficiency to our vibrating screens in numerous applications. Resistant to plugging and sustaining size accuracy, our perforated plate is available in many selections:

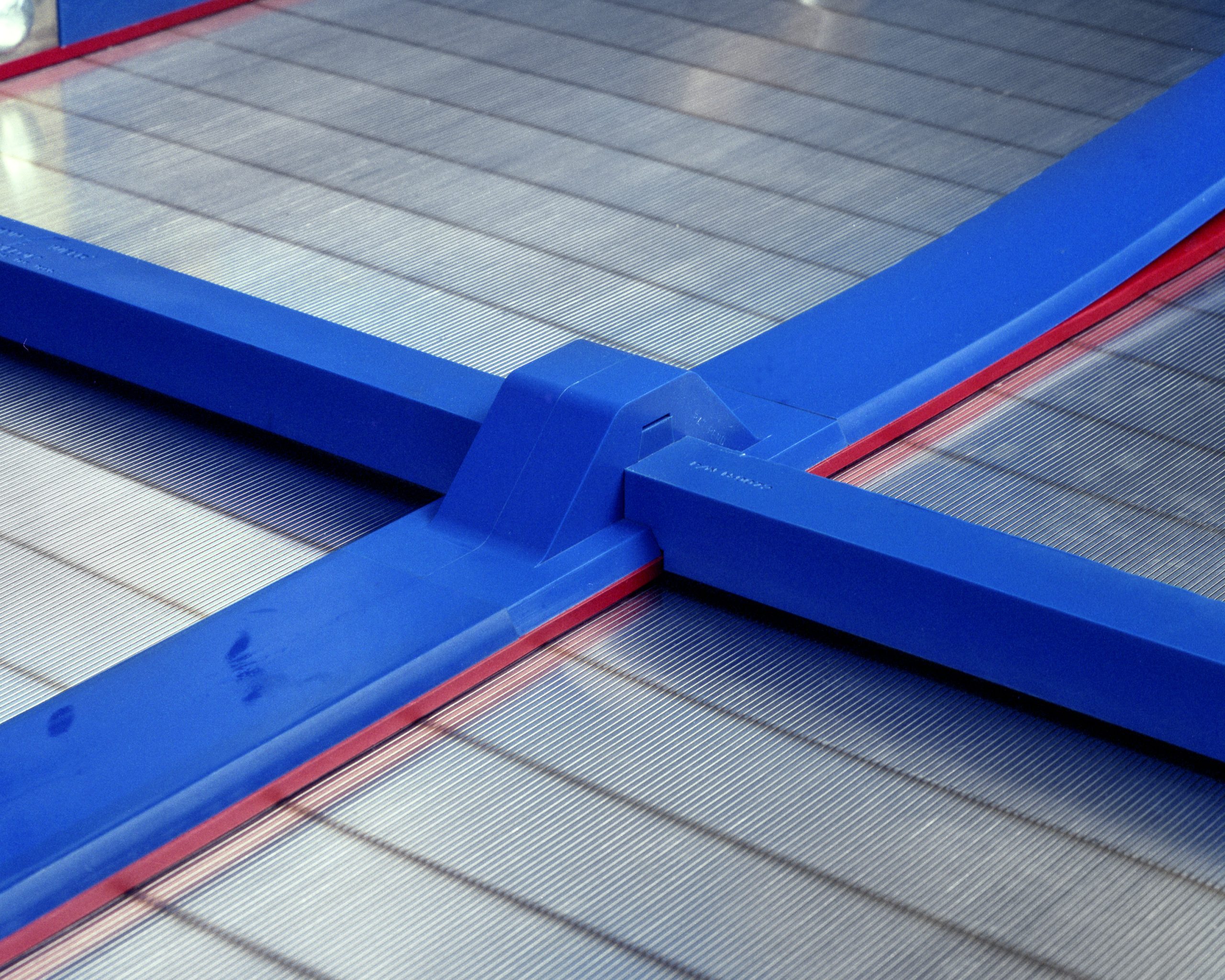

Conn-Weld PANELOK systems are easy to install and easier to maintain!

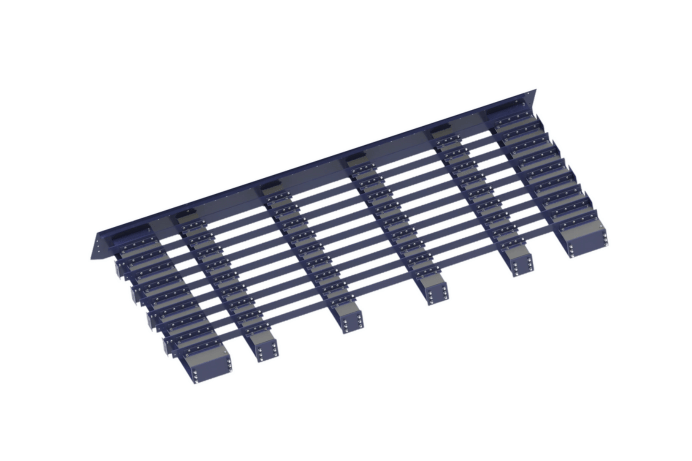

Conn-Weld’s Patented E-Z Deck Frame allows for worn sections to be replaced individually. Designed for easy installation in hard-to-reach places.