For 50 years, Conn-Weld has been a trusted partner in screening technology. Delivering custom-engineered solutions built for real-world applications.

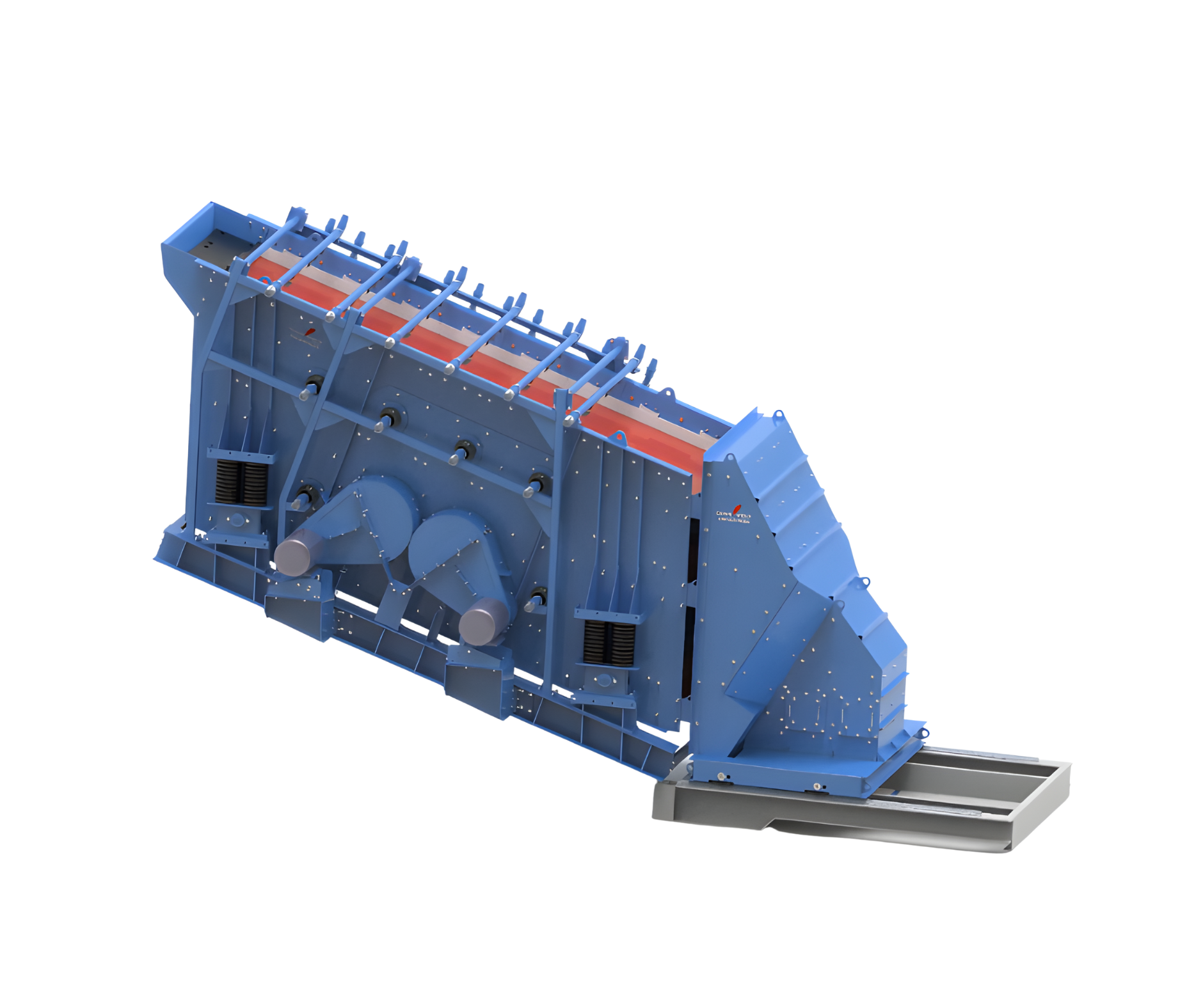

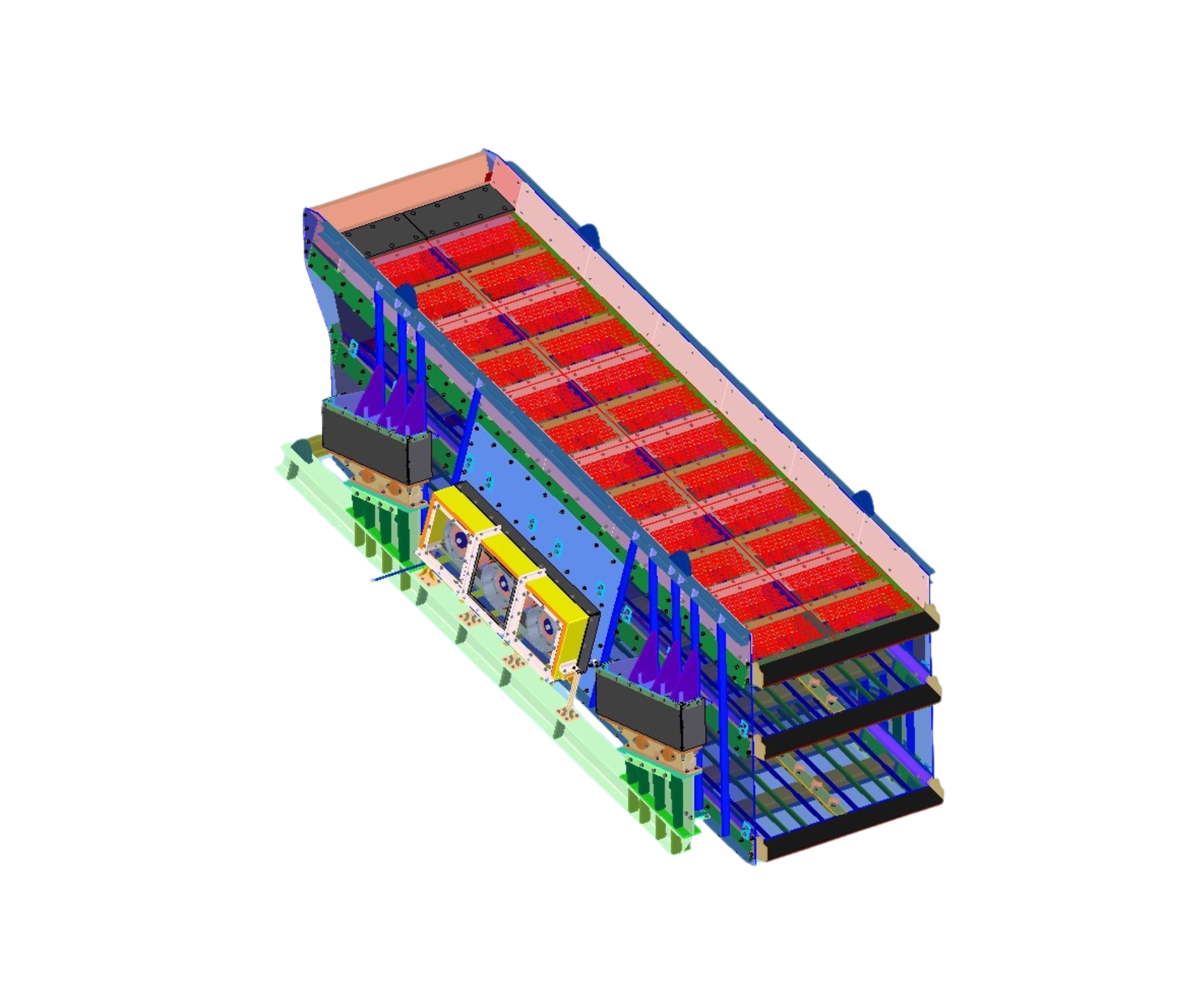

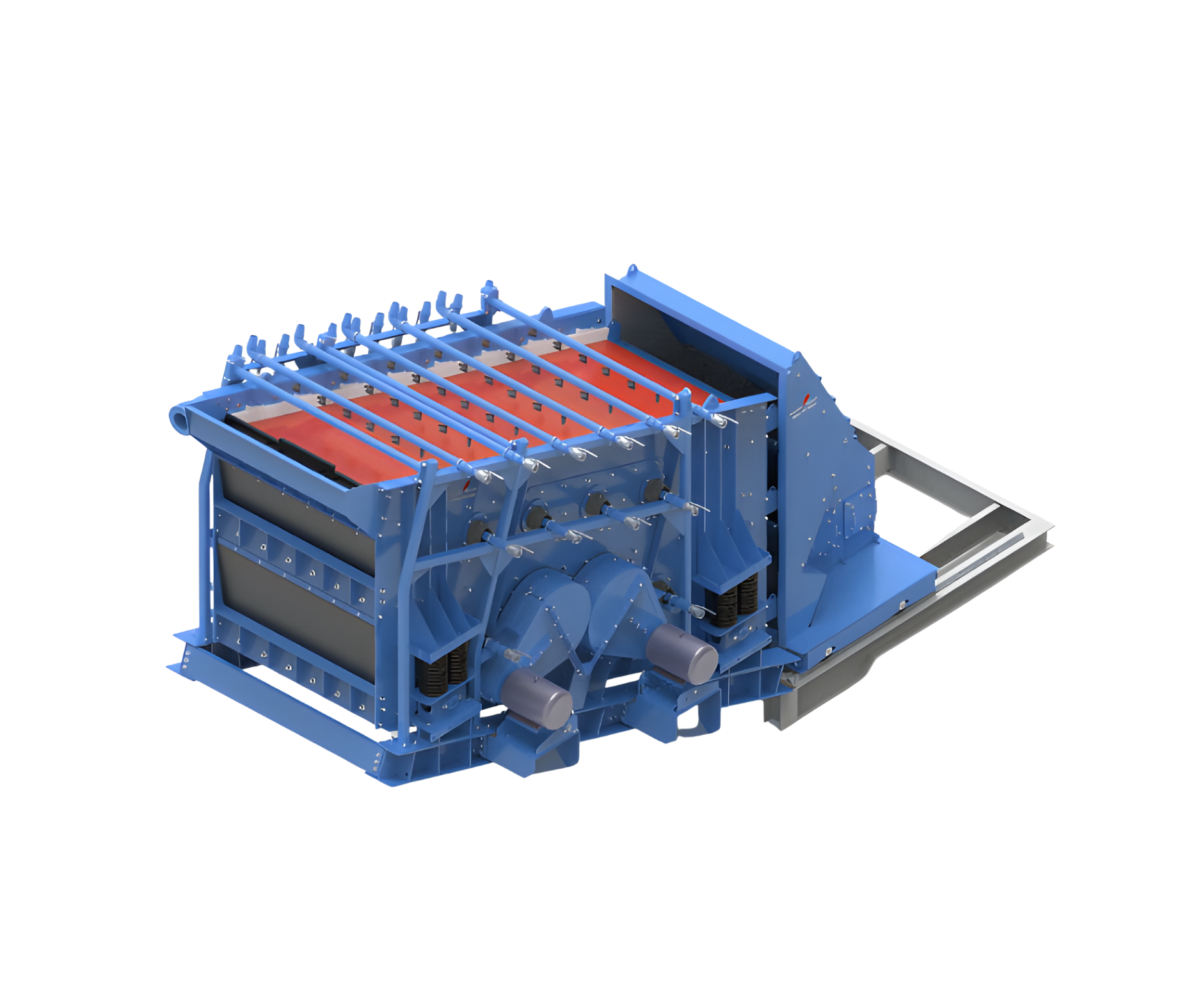

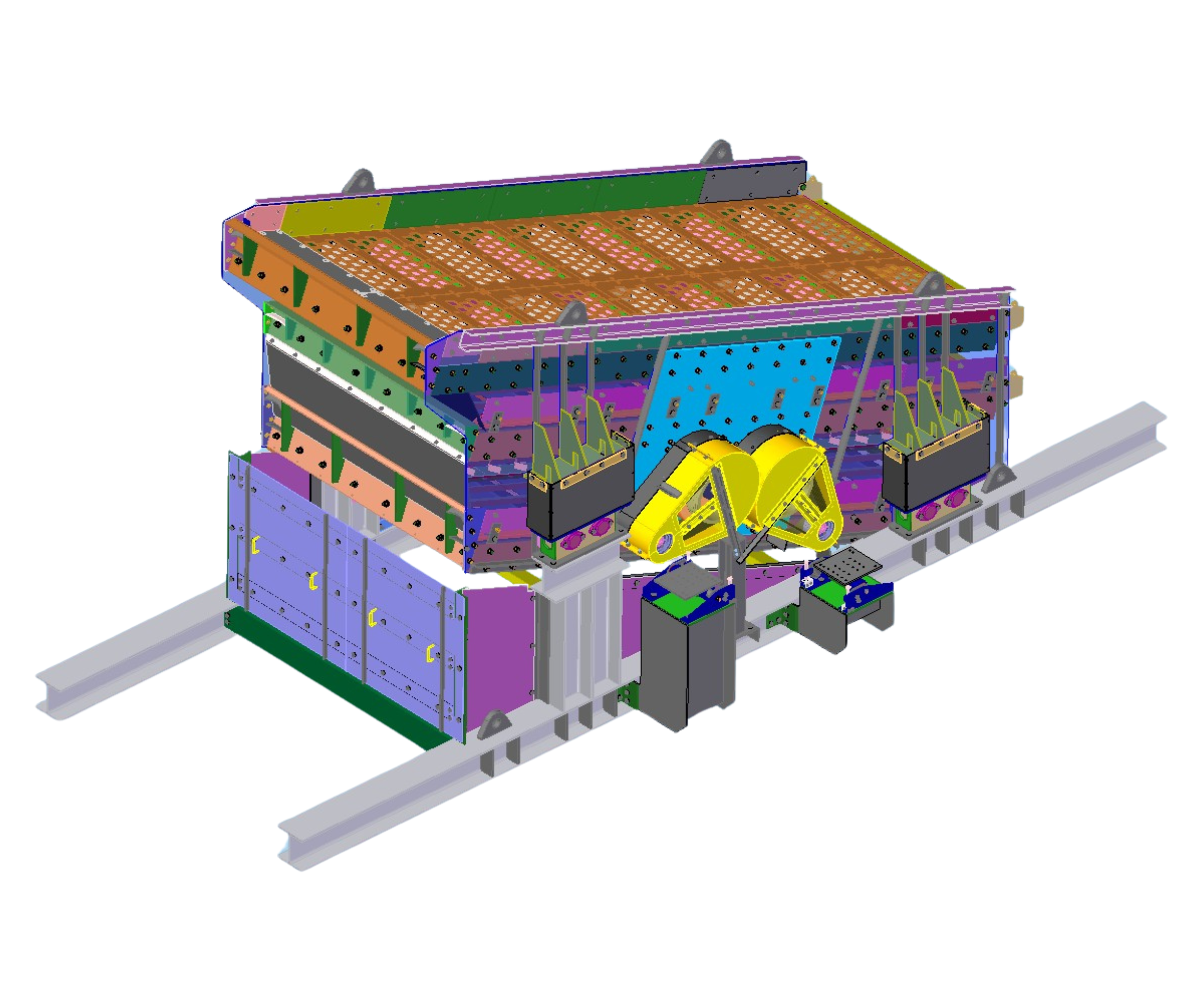

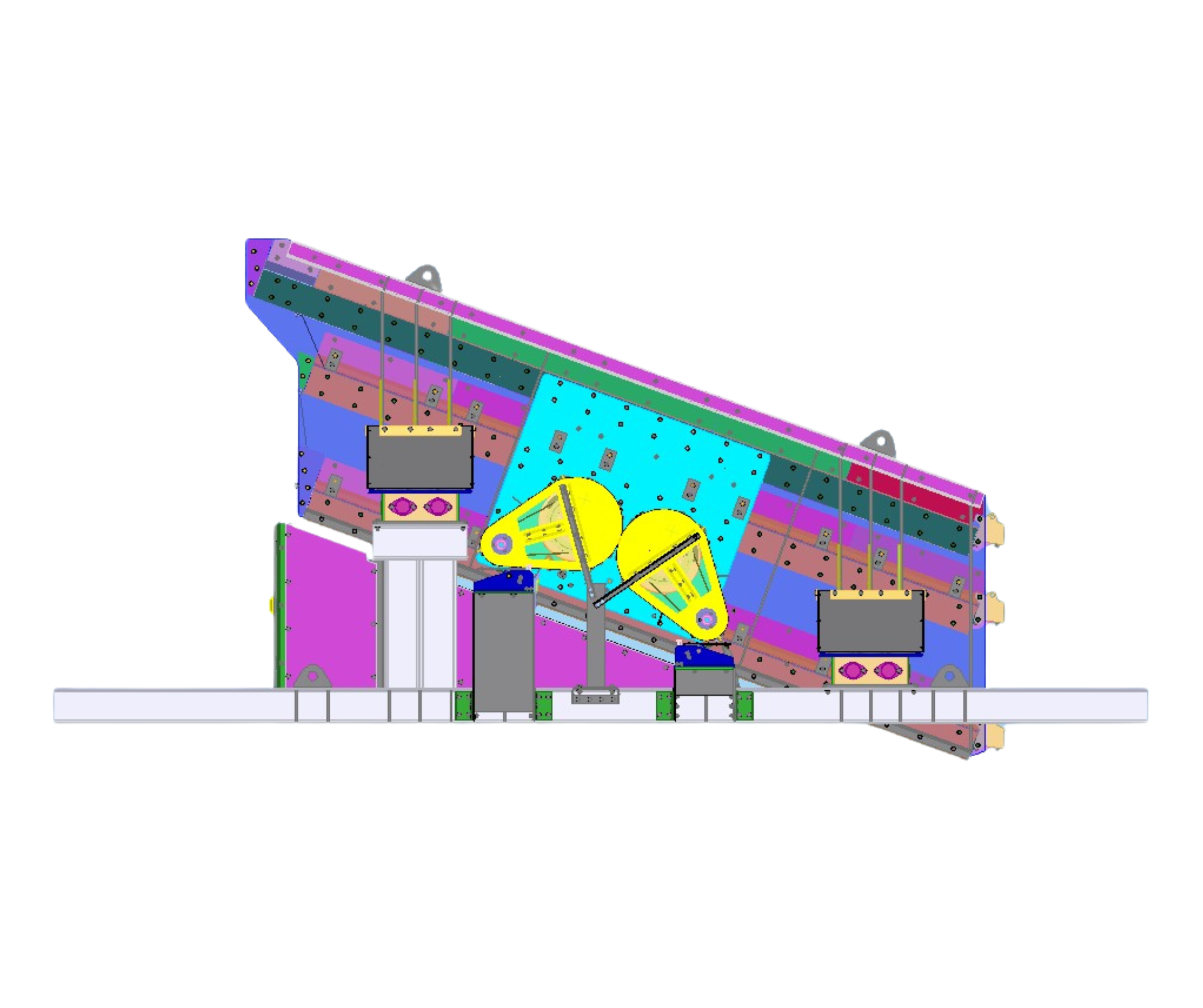

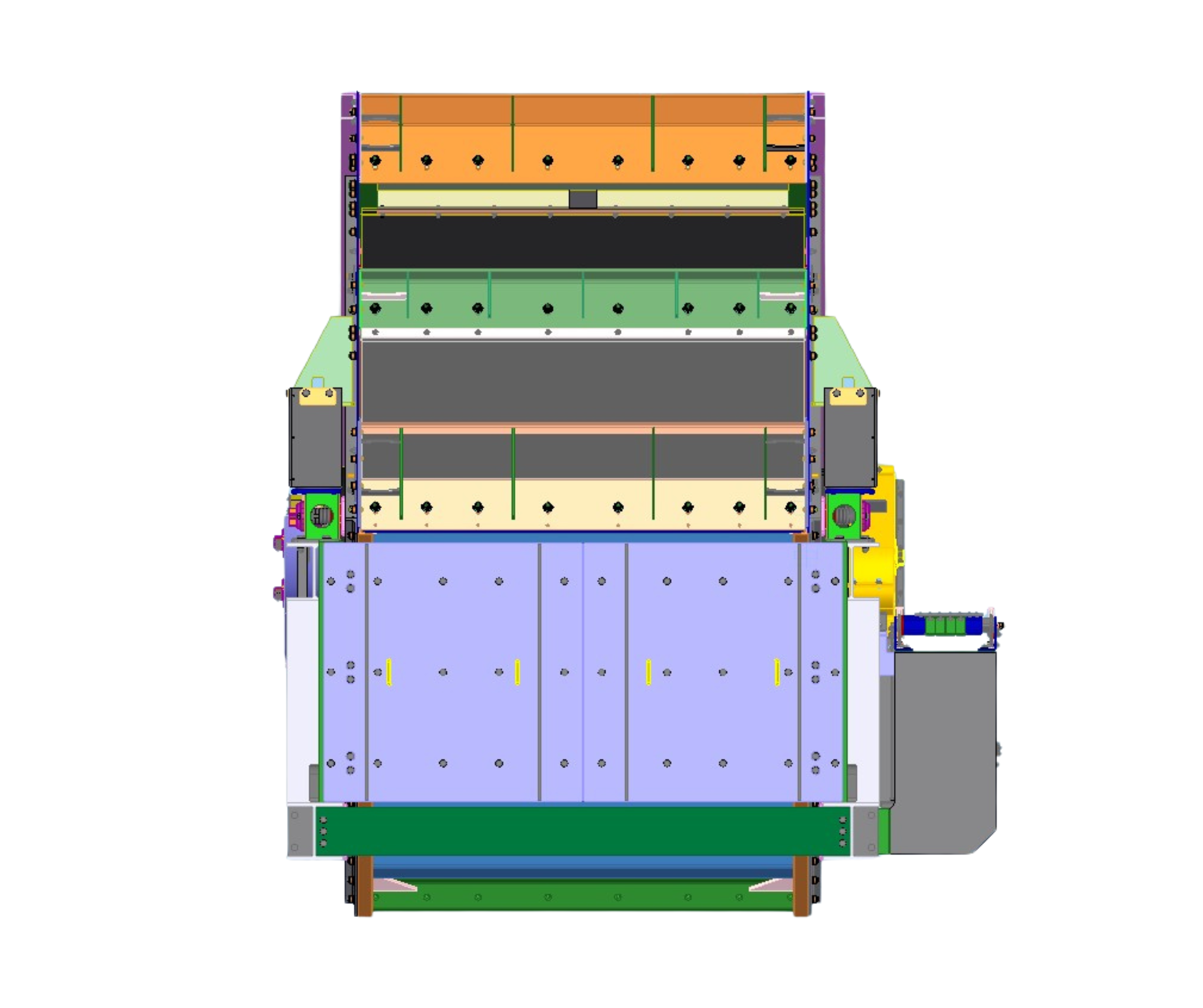

From vibrating screens and screen media to direct-fit components and on-site support, our solutions are designed to perform, last longer, and reduce downtime.

President of Conn-Weld

Vice President of Engineering

Vice President of Aggregates

Vice President of Hard Rock & Industrial Minerals

Director of Business Development

District Manager

District Manager

District Manager

District Manager

District Manager

Product & Applications Manager

Plant Supervisor

Engineering Manager

Communications, Marketing Coordinator

Communications, Content Specialist

Conn-Weld is expanding its presence across the West Coast!

Meet with one of our team members to discuss our engineering solutions, services, and support. Schedule or request information in regards to a conference or seminar training in our state-of-the-art Seminar & Conference Center.