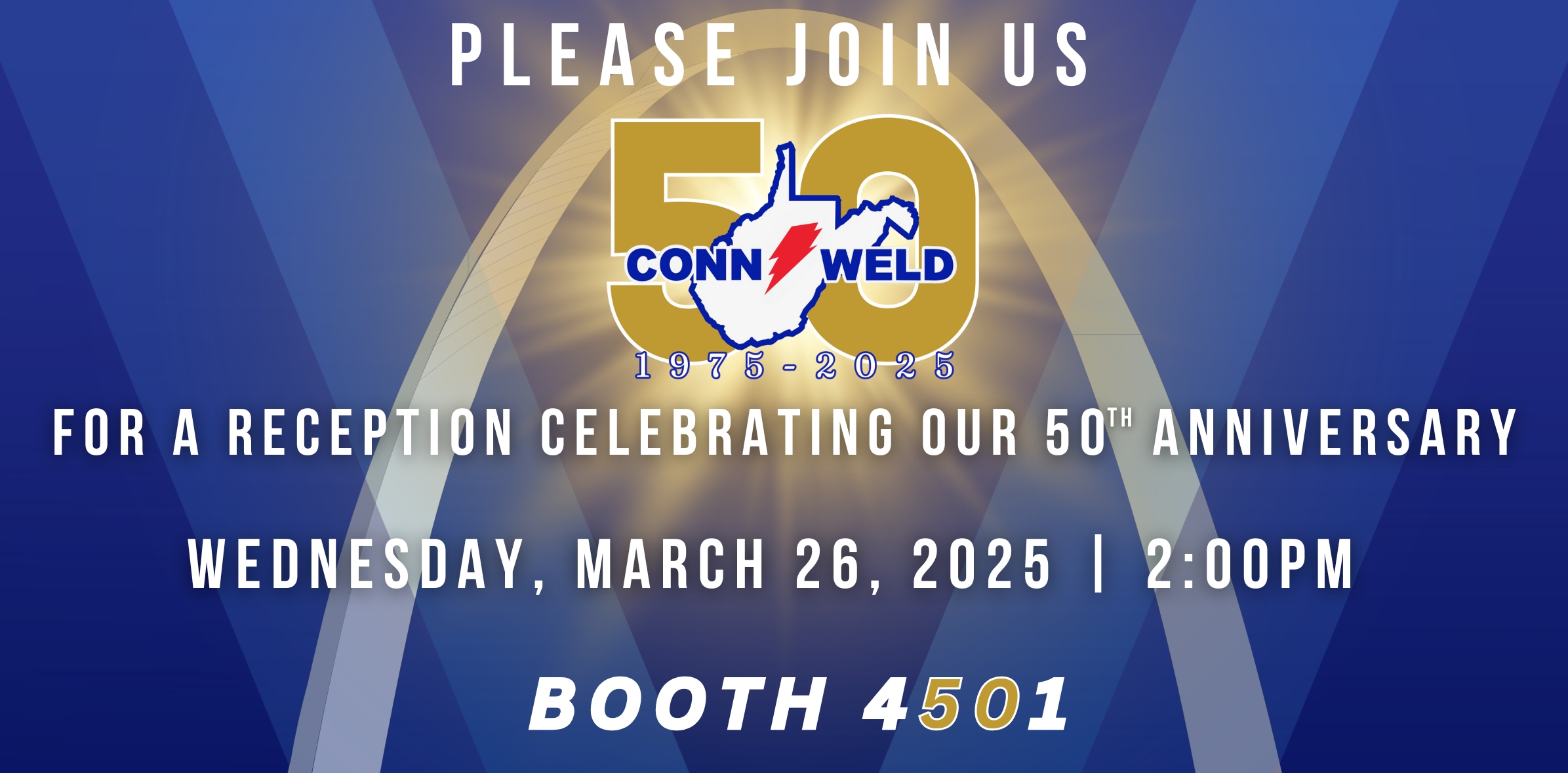

Celebrating our 50th Anniversary, Conn-Weld Industries will speak to a half-century in custom manufacturing as they highlight - The Products that Built Us and The People Who Define Us - the theme of Booth 4501. Visit our 50th Anniversary page to learn more!

Custom manufactured vibrating screens, separation solutions, building & designing products supporting recycling, numerous options to choose from, investing in our people, and communities since 1975.

Ask how we can improve your operational efficiency. Our team is ready to discuss the latest in custom engineering, our full line of equipment, replacement parts, and retrofitting capabilities.

PRESIDENT

DIRECTOR OF BUSINESS DEVELOPMENT

VICE PRESIDENT OF ENGINEERING

VICE PRESIDENT OF AGGREGATES

VICE PRESIDENT OF INDUSTRIAL HARD ROCK AND MINERALS

DISTRICT AND INTERNATIONAL SALES MANAGER

PRODUCT AND APPLICATION MANAGER

DISTRICT SALES MANAGER

SENIOR MINING ANALYST

DISTRICT SALES MANAGER

DISTRICT SALES MANAGER

DISTRICT SALES MANAGER

DISTRICT SALES MANAGER

DISTRICT SALES MANAGER

Meet with one of our team members to discuss our engineering solutions, services, and support!

FOLLOW US