Extreme Duty Scalping Screen Side Plate

Available in the following size: 8’ x 18’. Four-degree slope, reinforced at drive location to support reverse-mounted mechanism beam, lifting lugs, welded or bolted spring mounts.

REQUEST INFO

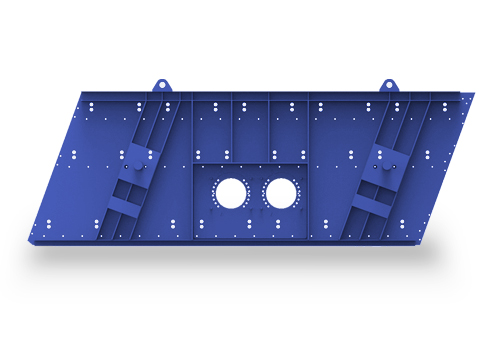

Dewatering Screen Side Plate

Available in sizes ranging from 3’ x 10’ to 8’ x 12’. Feed end declined at 45 degrees, reinforced at drive location, lifting lugs, welded or bolted spring mounts.

REQUEST INFO

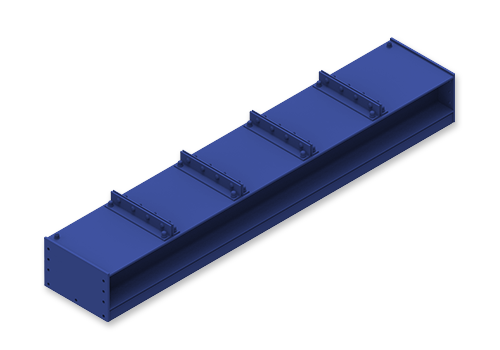

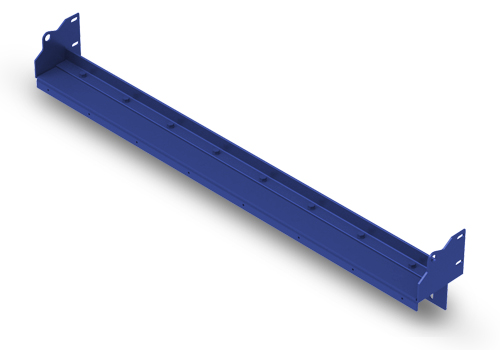

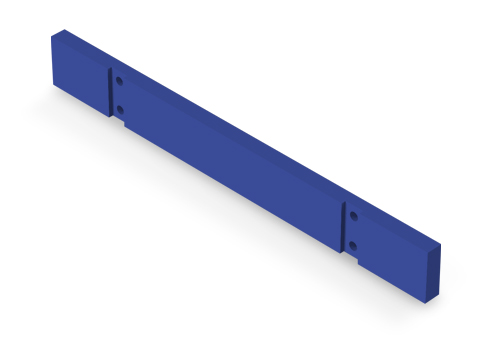

Double Beam Cross Member

Heavy-duty deck support systems are constructed with individual cross members. Made to match the customer's screen media. Wear liner options include AR, stainless steel, rubber, ceramic, and urethane.

REQUEST INFO

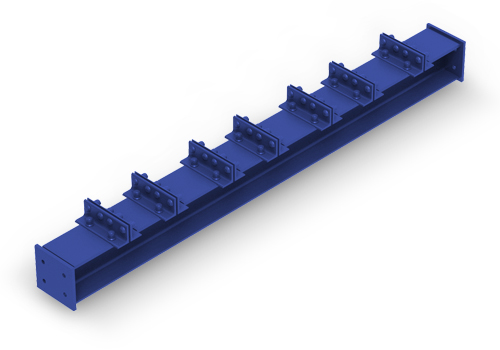

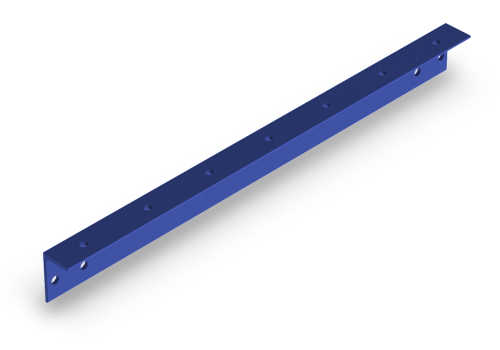

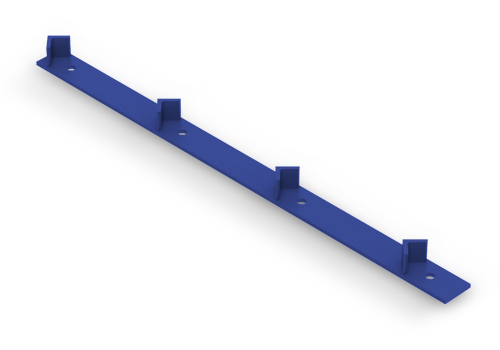

Single Beam Cross Member

Heavy-duty deck support systems are constructed with individual cross members. Made to match the customer's screen media. Wear liner options include AR, stainless steel, rubber, ceramic, and urethane.

REQUEST INFO

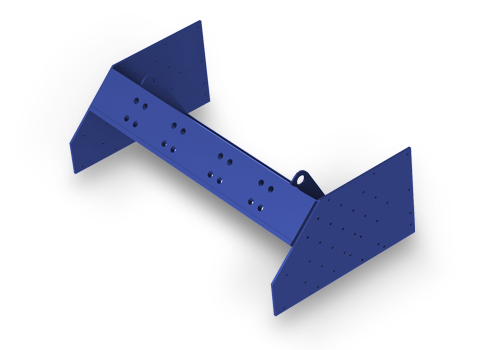

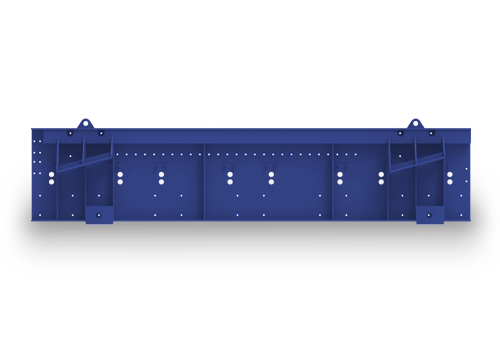

Mechanism Support Beam

Designed to accept a variety of mechanisms, beams are built to withstand the stresses and fatigue produced by mechanisms. Precision machining centers ensure smooth surfaces and accurate placement of mounting holes. Lifting eyes included for handling. Some wear protection (i.e., rubber, grout) may also be included.

REQUEST INFO

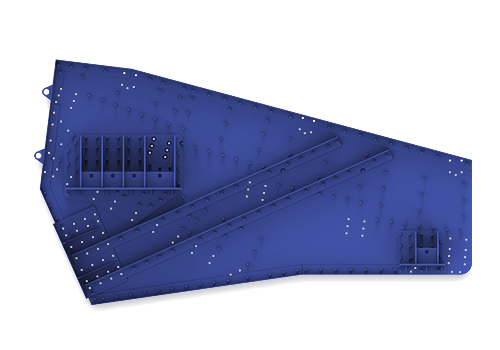

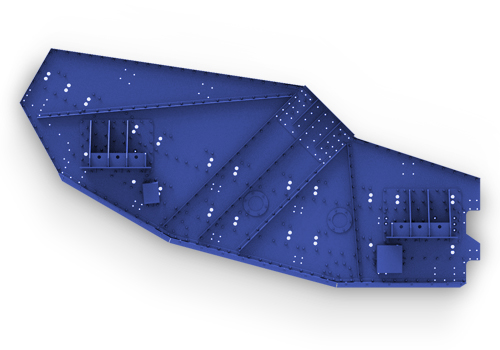

Banana Style Side Plate

Available in sizes ranging from 6’ x 20’ to 14’ x 28’. Multi-slope, reinforced at drive area, reinforced at transition locations, lifting lugs, welded or bolted spring mounts.

REQUEST INFO

Circular Motion Incline Side Plate

Available in sizes ranging from 4’ x 8’ to 10’ x 24’. Incline, welded stiffener, reinforced around the drive area, lifting lugs, welded or trunnion spring mounts.

REQUEST INFO

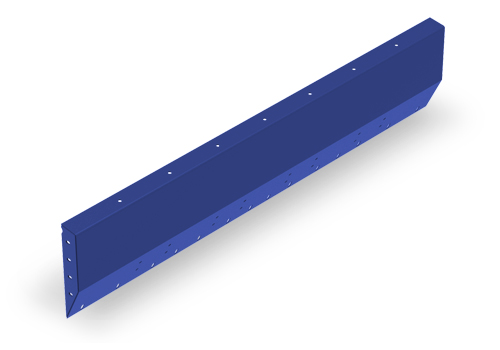

Horizontal Side Plate

Available in sizes ranging from 3’ x 14’ to 14’ x 20’. Horizontal, larger side plates reinforced at drive location, lifting lugs, welded or bolted spring mounts.

REQUEST INFO

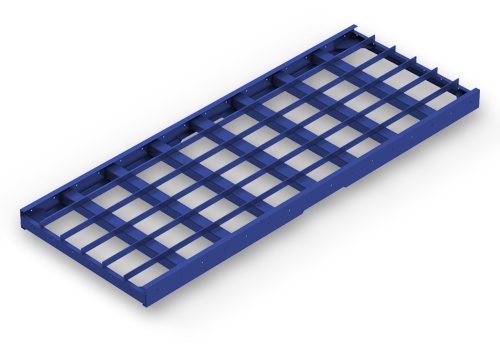

Deck Support Frame

Designed to properly secure the screen panels and withstand heavy loads. Deck frames can be retro-fitted or customized to accommodate any screen media. A variety of wear options available such as rubber, ceramic, and urethane lining. Multi-piece deck frames for easier installation in tight areas are also available.

REQUEST INFO

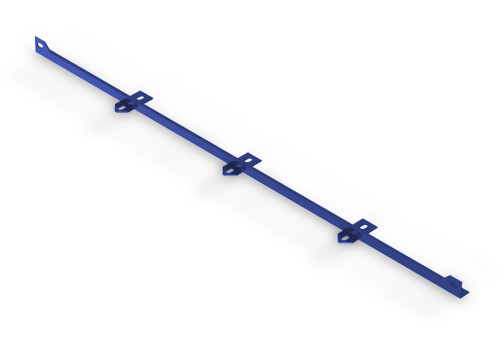

Screen Support Angles

Support the individual screen panels in vibrating screens designed with individual cross members. The design of these angles is based on the screen media. Huck pins/collars or nuts, bolts, and washers are provided for installation.

REQUEST INFO

Back Plate

Designed so that there is sufficient clearance for installation or removal of screen panels above the back plate. A rubber splash curtain can be attached to prevent spillage underneath the back plate.

REQUEST INFO

Discharge Lip

Furnished with an abrasion-resistant wear plate. Angle cross dam can be bolted on to help slow material movement. Available with AR liners, high-impact rubber, or other wear materials.

REQUEST INFO

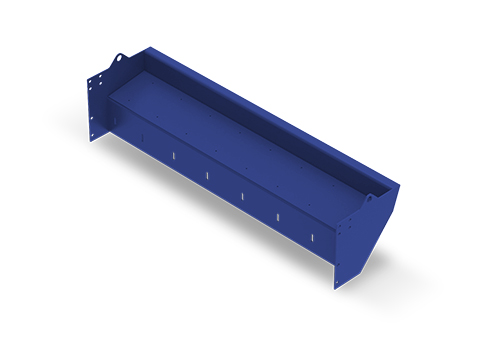

Feed Box

Furnished with an abrasion-resistant wear plate, other wear materials may be substituted. A rubber splash curtain preventing spillage is available for installation.

REQUEST INFO

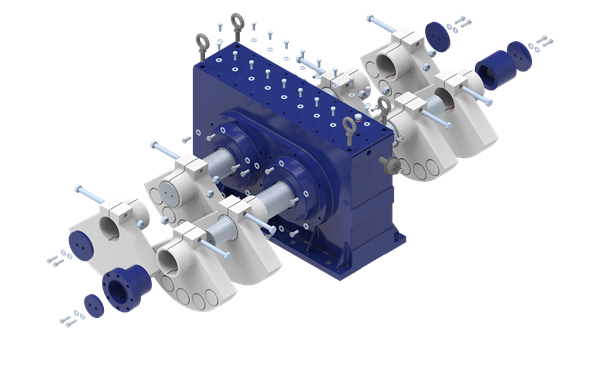

3.1 & 4.1 Mechanisms

Through-bolt system in the mounting surface of the mechanism lowers the possibility of cross threading and damaging the housing during installation. External counterweights lower probability of contaminants in the lubrication system. Center shaft allows for higher misalignment lowering amount of time to install drives.

REQUEST INFO

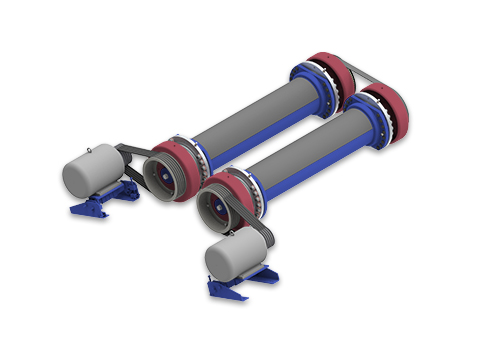

Cardan Shaft Assembly

Most commonly used with Banana Screens. Additional applications with dewatering, incline, and horizontal. Parts may be ordered individually or as sub-assemblies. Large inventory of parts and assembled mechanisms available. Contact us about our rebuild exchange program to facilitate lower downtime.

REQUEST INFO

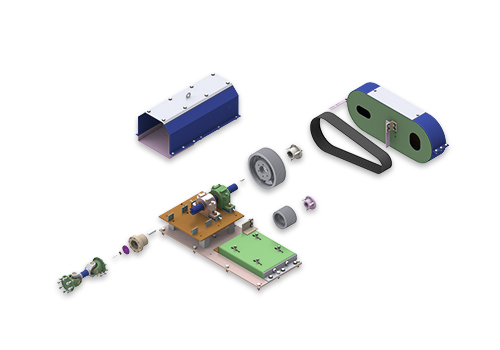

Drive Line Components

Replacement drive line assembly components for single, dual, and triple drive incline screens. Components include, timing sheave, timing belt, groove belt sheave, motor, motor base.

REQUEST INFO

Mechanism

G-Master® : 1000 series, 2000 series, 3000 series

Banana Style: 3.1s, 4.1s

Incline Mechanisms: 4400, 5500, 6500

Large inventory of parts and assembled mechanisms available. Contact us about our rebuild exchange program to facilitate lower downtime.

REQUEST INFO

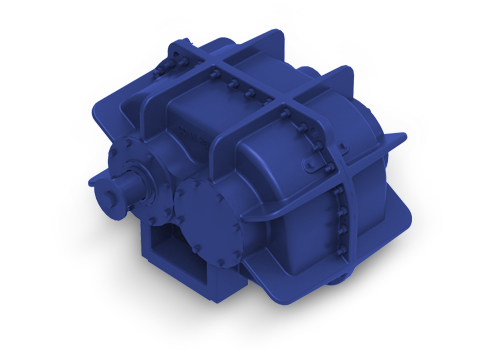

Eccentric Shaft Mechanism

Used in Circular Motion Incline Vibrating Screen mechanisms. Large inventory of parts and assembled mechanisms available. Contact us about our rebuild exchange program to facilitate lower downtime.

REQUEST INFO

Shaft Housing Cover (Molded)

Bolt on shaft housing cover, maximum wear protection, one inch overall thickness, rubber available in various thicknesses, molds to metal, secured with bolt-on straps.

REQUEST INFO

Shaft Housing Cover (Wrapped)

Bolt-on shaft housing wear protection, 3/8-inch rubber wraps around the shaft housing and bolts together.

REQUEST INFO

C-Style Clamp Bar

C-Style Clamping Bar used in hold down systems using woven wire and perforated plate screen media.

REQUEST INFO

UHMW Side-hold Downs

Conn-Weld offers both oak wood and UHMW side hold-downs. Optional sponge rubber provides for a better seal to the side plate. Our boltless side hold-down system eliminates holes, preventing leakage and provides faster installation time. Existing vibrating screen can be converted with urethane plugs.

REQUEST INFO

Cross Dams

Manufactured to meet customer’s requirements and match any type of screen media. The height of the cross dam can be adjusted. Sponge rubber seal seams between the screen media panels. Stainless steel available upon request.

REQUEST INFO

Center Hold Downs

Manufactured to meet the customer’s requirements and match any type of existing screen media. Deflector angles welded at each bolt hole reduce wear on bolts. Stainless steel is available upon request.

REQUEST INFO